The allure of a 40-foot container house is undeniable. It represents a unique fusion of sustainability, affordability, and modern design. But embarking on such a project requires careful planning and a deep understanding of what it truly entails. This comprehensive guide is designed to be your roadmap, demystifying the entire process from initial cost calculations to final design flourishes. Whether you're dreaming of a compact primary residence, a spacious vacation home, or a functional backyard studio, a 40-foot high cube container offers a robust and versatile canvas. We'll delve into the nitty-gritty of budgeting, explore practical and innovative floor plan options, and inspire you with design ideas that transform a cold steel box into a warm and inviting home. Our goal is to equip you with the knowledge needed to confidently decide if this innovative housing solution is the right fit for your vision and lifestyle, ensuring your project is both successful and satisfying.

Understanding the Core Appeal of a 40-Foot Container Home

Choosing a shipping container as a building block is more than an aesthetic decision; it's a strategic one. The 40-foot container home strikes a perfect balance between spaciousness and manageability. Unlike smaller units, it provides enough raw space to create a genuinely comfortable living area without the immediate need for combining multiple containers, thus simplifying the initial construction phase. The inherent strength of Corten steel provides a durable and resilient structure, resistant to the elements and pests. Furthermore, repurposing a container is a fundamentally eco-conscious choice, giving a second life to an object that would otherwise sit idle. This modular approach to construction also offers potential time savings, as a significant portion of the structure is already complete. However, it's crucial to understand that the journey involves navigating insulation, ventilation, and building codes to turn the industrial shell into a habitable and efficient dwelling.

- Sustainability: Repurposing decommissioned shipping containers reduces industrial waste and the demand for new building materials.

- Durability: Built to withstand harsh marine environments, these containers are incredibly strong, wind-resistant, and secure.

- Modularity: Their standardized dimensions allow for easy stacking and combining, enabling scalable and creative architectural designs.

- Cost-Effectiveness: While finishing costs add up, the base structure can be more affordable than traditional wood or brick framing.

- Speed of Construction: With the primary structure already in place, the on-site build time can be significantly reduced compared to conventional methods.

Breaking Down the Cost of a 40-Foot Container Home

One of the most common questions is, "How much does a 40-foot container home cost?" The answer is not a single figure but a range, typically spanning from $30,000 to well over $150,000. This vast disparity depends on factors like the container's condition, location, site work, interior finish level, and whether you hire professionals or take the DIY route. A used "one-trip" container is a popular budget-friendly option, while a new container offers pristine condition at a higher price. The real expenses begin after acquisition. Site preparation, including foundation pouring (a crucial and non-negotiable cost), utility connections (septic, water, electricity), and permits can account for a significant portion of the budget. Then comes the transformation: cutting openings for doors and windows, installing insulation, and interior framing, which are essential for comfort. Finally, the interior finishes—drywall, flooring, kitchen cabinets, and bathroom fixtures—where costs can vary dramatically based on your choices.

- Container Acquisition: $3,000 - $6,000 for a used 40ft high cube container.

- Site Preparation & Foundation: $5,000 - $20,000+ (slab, piers, or basement).

- Design & Permits: $2,000 - $10,000 (architect fees, engineering stamps, permit fees).

- Modification & Construction: $15,000 - $50,000+ (cutting, welding, framing, insulation, roofing).

- Utilities & Interior Finishing: $20,000 - $75,000+ (plumbing, electrical, HVAC, kitchen, bathroom, flooring).

Cost Comparison: Basic vs. Turnkey Finish

To better understand the financial commitment, it's helpful to visualize the cost spectrum. The following table outlines the key differences between a basic, DIY-leaning project and a full-service, turnkey build for a 40-foot container home. This comparison assumes a single-container structure and does not include the price of land.

| Cost Factor | Basic Finish (DIY-Heavy) | Turnkey Finish (Professional) |

| Container | Used, one-trip ($4,500) | New or refurbished ($6,000) |

| Foundation | Concrete piers ($6,000) | Reinforced slab ($15,000) |

| Modifications | Self-contracted cuts ($8,000) | Professional engineering & work ($25,000) |

| Insulation | Spray foam DIY kit ($3,500) | Professional spray foam ($7,000) |

| Interior Finishing | Budget materials, self-installed ($15,000) | Mid-to-high-end materials, professional install ($50,000) |

| Estimated Total | $37,000 | $103,000 |

Designing Your Layout: 40ft Container Home Plans

Creating a functional and feel-good layout within a long, narrow space is the most exciting part of the process. Effective 40ft container home plans prioritize flow, light, and multi-functional spaces. The standard interior dimensions of a high cube container are approximately 39' 6" long, 7' 9" wide, and 9' 6" high, offering around 300 square feet of floor space. The key to avoiding a tunnel-like effect is strategic placement of windows and doors to maximize cross-ventilation and natural light. Open-plan designs for the main living area are almost essential, combining the kitchen, dining, and living spaces into one cohesive zone. Private areas like the bedroom and bathroom are typically placed at one or both ends. Utilizing the vertical space is critical; the high cube model allows for lofted beds, high storage shelves, or even mezzanine levels, effectively doubling the usable space without increasing the footprint.

- The Open Plan: Combine kitchen, living, and dining into a single, airy space in the center of the container.

- End-Suite Privacy: Place the bedroom and bathroom at one end for maximum privacy, separated by a door from the main living area.

- Lofted Sleeping: Build a sleeping loft above one end of the container, freeing up the floor below for a living room, office, or second bedroom.

- Multi-Container Configurations: For more space, plan to join two or more containers in an L-shape, T-shape, or side-by-side configuration.

- Outdoor Integration: Design large sliding glass doors that open onto a deck or patio, extending the living space outdoors.

Single vs. Double Container Layouts

When your space needs exceed a single container, combining two units opens a world of possibilities. This is a fundamental decision in your planning process. A single-container layout is a masterclass in efficient, minimalist living, perfect for a single person, a couple, or a vacation home. The challenge is optimizing every square inch for multiple functions. In contrast, joining two 40-foot shipping container homes effectively doubles your width, allowing for a more conventional room layout with a central corridor, separate bedrooms, and a much more spacious feel. You can create a courtyard between them or stack them for a two-story home. The trade-off, of course, is a near-doubling of your base construction and modification costs, but the gain in comfort and marketability can be significant.

| Aspect | Single Container Layout | Double Container Layout |

| Total Square Footage | ~300 sq ft | ~600 sq ft (on one level) |

| Ideal For | Individuals, couples, vacation homes, studios | Small families, those desiring more space |

| Layout Feel | Efficient, linear, cozy | Spacious, can mimic traditional home layouts |

| Cost Implication | Lower base cost, simpler foundation | Higher base cost, more complex foundation and joining |

| Design Challenge | Avoiding a "hallway" feel, maximizing storage | Creating a seamless flow between containers, roof design |

Creative Design Ideas to Elevate Your Container Home

Moving beyond the basic steel box, the design phase is where your personality shines. The industrial aesthetic of a container is a fantastic starting point, but the ways to soften and personalize it are endless. A key design strategy is to incorporate elements that contrast with the industrial nature of the steel. Using warm materials like wood cladding on portions of the exterior or for interior accent walls can instantly make the space feel more inviting. Similarly, installing large windows and glass doors is non-negotiable; they flood the interior with light, provide connection to the outdoors, and make the space feel dramatically larger than it is. For those looking to push boundaries, combining containers at different angles or cantilevering a section creates stunning architectural drama. The interior design can range from sleek and modern minimalist to a more rustic, industrial chic, depending on your choice of finishes, fixtures, and lighting.

- Contrasting Materials: Combine the raw steel with natural wood (for decking or siding), stone accents, or even green walls.

- Expansive Glazing: Use full-height sliding glass doors or picture windows to erase the boundary between inside and outside.

- Pop-Out Sections: Create additional space by welding a "pop-out" section for a bathroom or cozy reading nook, breaking the rigid rectangular shape.

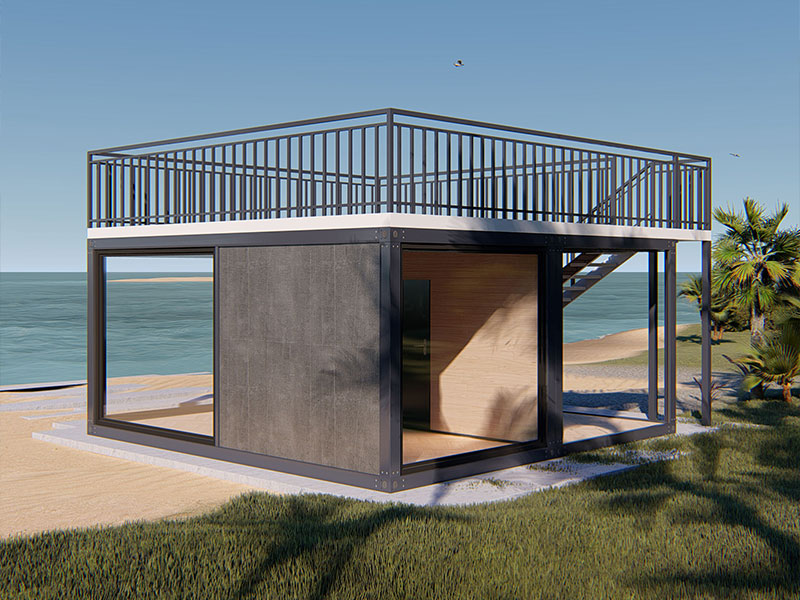

- Rooftop Retreat: Utilize the flat roof for a deck garden, complete with seating and planting, offering valuable outdoor space.

- Industrial Chic Interiors: Embrace the container's origins by leaving some steel walls exposed and using Edison bulb lighting and metal fixtures.

Navigating the Build: Permits and Professional Help

Before you purchase a single container, the most critical step is understanding your local building codes and permit requirements. This is often the biggest hurdle for aspiring container homeowners. Zoning laws will dictate where you can place your home, while building codes will specify the requirements for everything from structural modifications and insulation R-values to egress window sizes and ceiling heights. Finding a 40-foot container home builder with specific experience is highly recommended. A general contractor unfamiliar with welding and working with steel may cause more problems than they solve. An experienced architect or engineer can ensure your plans are structurally sound, especially when cutting large openings, and will provide the stamped drawings necessary for permit approval. Navigating this bureaucratic landscape can be time-consuming and frustrating, but it is absolutely essential for ensuring your home is safe, legal, and insurable.

- Research Local Codes: Contact your local city or county building department early to understand zoning restrictions and code requirements.

- Secure Professional Plans: Invest in professionally drawn and engineered plans. This is not the place to cut corners.

- Hire Specialized Contractors: Seek out builders, welders, and insulators who have direct experience with container construction.

- Budget for Permits: Factor in the cost and time required for the permit application process, which can take several months.

- Schedule Inspections: Understand the inspection milestones (foundation, framing, electrical, plumbing, final) required by your local jurisdiction.

Insulation Options for a Comfortable Home

Transforming a metal box into a comfortable, energy-efficient dwelling hinges on one crucial element: insulation. The wrong choice can lead to a home that is unbearably hot, cold, or prone to condensation, which causes rust. The three most common cheap 40 foot container homes actually avoid skimping on insulation, but rather choose the most cost-effective method that suits their climate. Spray foam insulation is often considered the gold standard for containers because it provides a high R-value per inch, creates an air and vapor barrier, and adheres directly to the steel walls, preventing thermal bridging. However, it is among the more expensive options. Rigid foam board is a DIY-friendly alternative that can be effective if all seams are meticulously sealed. For those seeking a natural material, mineral wool batts offer good fire resistance and soundproofing but require a built-out frame and careful installation to avoid gaps.

| Insulation Type | Pros | Cons |

| Spray Foam (Closed-cell) | High R-value, seals air leaks, moisture barrier | Highest cost, requires professional installation |

| Rigid Foam Board | Good R-value, moisture resistant, DIY possible | Requires meticulous sealing of seams, can be bulky |

| Mineral Wool (Batt) | Fire resistant, excellent soundproofing, vapor permeable | Requires a frame, can settle leaving gaps, lower R-value |

| Reflective/Bubble Foil | Thin, good for radiant heat, very cheap | Low overall R-value, must have an air gap, fragile |

FAQ

How long does a container home last?

A well-maintained 40-foot container house can last for decades, potentially 25-50 years or more. The longevity depends primarily on how effectively corrosion (rust) is managed. The core Corten steel is incredibly durable, but modifications like cutting doors and windows can expose untreated steel to the elements. The key to a long lifespan is a high-quality paint job, proper waterproofing of the roof and all seams, and, most critically, the installation of a effective ventilation system to prevent condensation buildup on the inside of the steel walls, which is a primary cause of rust from the inside out. Regular inspections and touch-ups of the exterior paint will ensure your container home remains structurally sound for a lifetime.

Can I build a container home myself?

While a highly motivated and skilled DIY enthusiast can tackle significant portions of a 40-foot container home project, it is not advisable to attempt the entire build alone. Tasks like welding structural modifications, pouring the foundation, and installing electrical and plumbing systems typically require licensed professionals to ensure safety and compliance with building codes. However, there are many areas where DIY can save money, such as interior framing, installing insulation (if using batts or boards), laying flooring, painting, and installing kitchen cabinets. The most successful approach is often a hybrid one: hiring professionals for the critical, structural, and technical work (foundation, welding, utilities) and managing the interior finishing work yourself.

Are container homes hot in the summer?

Yes, a metal box will heat up in the sun without proper planning. This is a common and valid concern. However, this issue is entirely solvable with a multi-pronged approach to thermal management. The first and most important defense is high-quality insulation, which creates a barrier between the external steel and the interior living space. Secondly, reflective or light-colored exterior paint can significantly reduce solar heat gain. Thirdly, strategic placement of windows and doors to facilitate cross-ventilation is crucial for passive cooling. Finally, installing a standard HVAC system or energy-efficient mini-split unit is standard practice for maintaining a comfortable temperature year-round, just as it is in a traditional home. A well-insulated container home can be just as comfortable as any other modern building.

How do I find land for a container home?

Finding suitable land for a 40-foot shipping container home involves the same process as for a traditional home but with extra diligence. You must research zoning ordinances and covenants (CC&Rs) for the specific parcel you are interested in. Some areas have restrictions on the types of materials allowed for construction and may not explicitly permit shipping containers. Start by contacting the local planning and building department for any parcel you are considering. Be upfront about your intention to build a container home and ask about any relevant codes or restrictions. Rural areas often have more flexible building codes, making them a popular choice for alternative housing. It is always safer to get approval in writing before purchasing the land.

Are container homes cheaper than regular houses?

The answer is nuanced: they can be, but they aren't automatically. The savings come primarily from the lower cost of the initial structural shell compared to traditional wood framing. However, the expenses for the foundation, utility connections, interior finishing, and labor are largely the same. Where costs can escalate is in the specialized modifications: cutting steel, welding, and spray foam insulation. If you are able to do a significant amount of the labor yourself and source materials wisely, you can build a cheap 40 foot container home for less than a comparable traditional house. However, if you hire a turnkey company to handle everything, the final cost per square foot may be very similar to, or even exceed, that of a conventional build. The value is often found in the durability, speed of construction, and sustainable aspect rather than just the bottom line.