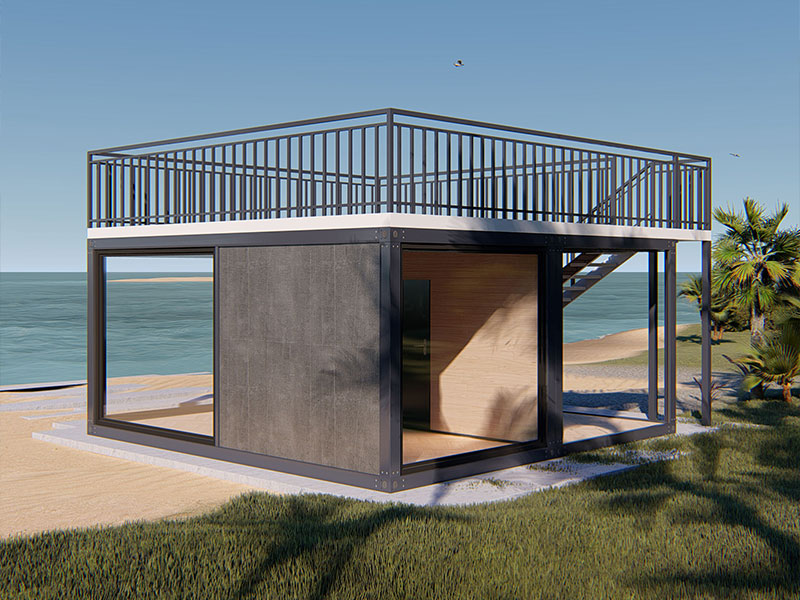

The dream of owning a home is becoming increasingly difficult to achieve, but innovative and affordable solutions are emerging. Building a home from shipping containers has captured the global imagination as a viable, sustainable, and cost-effective path to homeownership. This guide is designed for beginners, walking you through the entire process of how to create your own cheap container house. We'll demystify the steps, from initial planning and budgeting to the final touches, ensuring you have a clear roadmap for your project. This approach to building is not just about saving money; it's about embracing a minimalist, efficient, and creative lifestyle without compromising on quality or comfort.

Planning and Budgeting Your Container Home

Before you purchase a single container, meticulous planning is the most critical step for success. This phase sets the foundation for your entire project, helping you avoid costly mistakes and delays. It involves defining your needs, understanding the financial commitment, and navigating the legal landscape. A well-defined plan will guide every subsequent decision, from the type of containers you source to the interior finishes you choose. Rushing this stage is the most common error beginners make, so take your time to research, sketch, and calculate thoroughly. This upfront investment of time will pay massive dividends in smooth execution later on.

- Create a detailed list of your must-haves versus nice-to-haves (e.g., number of bedrooms, open-plan living).

- Research your local climate to inform insulation and HVAC choices, which are crucial for a metal structure.

- Set aside a contingency fund of at least 15-20% of your total budget for unexpected expenses.

Creating a Realistic Budget for a Cheap Container Home

A realistic budget is the backbone of any successful cheap container house project. The cost of the containers themselves is often just a fraction of the total expense. You must account for site preparation, foundation, insulation, cutting and welding, plumbing, electrical, interior finishing, and labor. Underestimating these costs is a pitfall for many first-time builders. It's essential to get quotes from multiple contractors for each phase of the project if you're not doing it yourself. Remember, the goal is affordability, not just the lowest possible price; investing in quality insulation and structural modifications is non-negotiable for safety and comfort.

- Container Acquisition: 10-20% of total budget.

- Site Preparation & Foundation: 15-25% of total budget.

- Insulation & Structural Modifications (cutting, welding): 20-30% of total budget.

- Interior & Exterior Finishing: 25-35% of total budget.

Understanding Legalities: Permits and Zoning Laws

Navigating the legal requirements is a non-negotiable step that can make or break your project. Zoning laws, building codes, and permit requirements vary dramatically by country, state, and even municipality. Some areas enthusiastically embrace alternative housing, while others have strict regulations that may not easily accommodate container homes. It is imperative to contact your local building department early in the planning process. Present your preliminary plans and ask specific questions about requirements for foundations, egress windows, ceiling heights, and structural engineering certifications. Securing the proper container home building permits might seem tedious, but it ensures your home is safe, legal, and insurable.

- Schedule a pre-application meeting with your local planning department.

- Hire a local architect or engineer familiar with container construction and local codes.

- Be prepared to submit detailed architectural and engineering plans for review.

- Understand the covenants and restrictions if you are building within a homeowners association (HOA).

Sourcing and Preparing Your Containers

Choosing the right containers is more complex than simply finding the cheapest option available. The quality, condition, and type of container you select will directly impact your budget, structural integrity, and the amount of work required to make it habitable. "One-trip" containers are newer and have minimal wear, while "wind-watertight" (WWT) containers are older but are certified to not leak. You also need to decide between standard 20ft or 40ft containers or opt for high-cube containers that provide extra vertical space. Visiting a container depot to physically inspect your potential units is highly recommended to check for dents, rust, and floor condition.

- Always ask for the container's history and condition report from the supplier.

- Check for markings like "CORTEN steel," which indicates weather-resistant steel.

- Inspect the interior flooring for signs of chemical spills or rot if it's wood.

Where to Find Affordable Shipping Containers

Finding affordable shipping containers for sale requires some legwork. The most common sources are container leasing companies and shipping lines that sell their retired units. Local container sales companies are also a good option as they often have a variety of grades in stock and can handle delivery. Online marketplaces can connect you with sellers, but be cautious and insist on seeing the container before purchasing. Prices fluctuate based on location, demand, and steel prices. Sometimes, buying used containers can save you 40-60% compared to new ones, making them a key component in achieving a cheap container house.

- Container leasing companies (e.g., companies that lease to shipping lines).

- Local container modification and sales specialists.

- Online marketplaces and classified ads (exercise caution and verify condition).

- Directly from shipping ports (can be cheaper but may require larger quantity purchases).

Essential Modifications: Cutting, Insulating, and Framing

Once you have your containers, the real transformation begins. This stage involves cutting openings for doors and windows, which must be done carefully to avoid compromising the structural integrity of the unit. Steel reinforcing members must be welded around any new openings. Next, insulation is arguably the most important investment for comfort. A metal box conducts heat and cold efficiently, so choosing the right insulation—such as spray foam, panel systems, or eco-friendly options like rock wool—is critical. Finally, an internal frame is often built inside the container to allow for running electrical wiring, plumbing, and attaching drywall, creating a traditional wall system inside the robust steel shell.

- Hire a professional welder for any cutting and structural modifications.

- Spray foam insulation provides excellent thermal performance and an air seal but is more expensive.

- Panel systems (like PIR panels) are effective and can be installed faster but may have higher upfront material costs.

- Plan your window and door placements to align with your interior layout and maximize natural light.

| Insulation Type | Pros | Cons | Best For |

| Spray Foam | High R-value, air seals gaps, moisture resistant | Higher cost, requires professional installation | All climates, maximum efficiency |

| Panel (PIR) | Good R-value, quick installation, rigid | Can be costly, creates thermal bridging at joints | DIY projects, moderate climates |

| Batt (Fiberglass/Rock Wool) | Low cost, DIY-friendly | Lower R-value, requires a framing cavity, vapor barrier needed | Budget builds in mild climates |

Construction and Finishing

The construction phase is where your plans become a physical reality. It starts with preparing the site and pouring a solid foundation, which is crucial for supporting the concentrated weight of the containers. Common foundation types include concrete piers, strip foundations, and full concrete slabs. Once the foundation is set, the containers are carefully placed using a crane or heavy machinery and welded together to form a single, unified structure. From here, the process mirrors traditional home building: installing roofing (if a multi-container design requires it), running all electrical and plumbing systems through the pre-planned channels, and insulating the walls and ceiling. This phase requires close coordination between various tradespeople to ensure everything fits perfectly within the compact space.

- Ensure the foundation is perfectly level and square before container placement.

- Coordinate the crane operator, welder, and project manager for placement day.

- Run all electrical conduits and plumbing PEX lines before insulating and closing up the walls.

Interior Design Ideas for Small Container Spaces

Designing the interior of a container home requires clever thinking to maximize every square foot. The key is to embrace an open-plan layout for living areas and use multifunctional and space-saving furniture. Strategic use of light colors, large windows, and mirrors can make the narrow space feel much larger and brighter. Lofted bedrooms are a popular choice to free up floor space, while built-in storage solutions like drawers under stairs or benches with hidden compartments help reduce clutter. The linear nature of a container can be used to create a natural flow through the home, from public spaces at one end to private spaces at the other. The goal is to create a functional and comfortable home that feels spacious, not cramped.

- Utilize vertical space with high ceilings and mezzanine levels for sleeping or storage.

- Choose a cohesive color palette to create a sense of flow and openness.

- Install large sliding or glass doors to blur the line between indoor and outdoor living.

- Invest in custom-built furniture designed to fit awkward corners and maximize utility.

Connecting Utilities and Off-Grid Options

Connecting your cheap container house to municipal utilities (grid-tie) or setting it up for off-grid living is a fundamental decision that affects your lifestyle and budget. Grid-tie connection involves hiring licensed electricians and plumbers to connect your home to local water, sewer, and power lines, following all local codes. This is often the most straightforward path. However, the compact and efficient nature of container homes makes them ideal candidates for off-grid container homes. This approach involves installing solar panels, a battery bank, a composting toilet, and a water collection and filtration system. While the initial investment for off-grid systems is higher, it eliminates monthly utility bills and offers complete energy independence, which is a form of long-term savings.

- Consult with off-grid specialists to correctly size your solar system and battery bank based on your energy needs.

- Rainwater harvesting systems require storage tanks, pumps, and a robust filtration system for potable water.

- Composting or incinerating toilets are excellent water-saving solutions for off-grid setups.

- Even for grid-tied homes, incorporating some solar panels can significantly reduce electricity costs.

| System | Grid-Tie Option | Off-Grid Option | Considerations |

| Power | Connection to local power lines | Solar panels + battery bank + generator backup | Off-grid requires significant sun exposure and higher upfront cost |

| Water | Connection to municipal water | Well or rainwater collection + filtration + storage tanks | Water rights and rainfall patterns dictate off-grid viability |

| Waste | Connection to sewer or septic tank | Composting toilet, greywater system | Septic systems require space and soil percolation tests |

FAQ

How long does it take to build a container home?

The timeline for building a container home can vary widely based on complexity, size, and whether you are doing it yourself or hiring contractors. A simple, single-container home with a straightforward design might be completed in as little as 3-4 months from planning to move-in. A larger, multi-container home with custom designs and off-grid systems will typically take 6 to 12 months. The most time-consuming phases are often the planning and permit approval stage, which can take several months, and the modification and insulation of the containers themselves. Having all your materials and tradespeople lined up before you start is crucial for avoiding delays.

Are container homes safe in extreme weather?

Yes, when designed and constructed properly, container homes can be very safe in extreme weather. Their corrugated steel construction makes them inherently strong and resistant to high winds, making them suitable for hurricane-prone areas. They can also be designed to handle heavy snow loads. The key to safety lies in three factors: a solid foundation that anchors the structure to the ground, proper engineering that ensures the structural integrity is maintained after cutting doors and windows, and correct insulation to prevent condensation which can lead to rust over time. It is absolutely essential to work with an engineer who has experience with container structures to ensure your home meets all local building codes for wind and snow.

What is the biggest challenge when building a container home?

While there are several challenges, the single biggest one is often addressing insulation and condensation. A steel container is a thermal bridge, meaning it efficiently transfers heat and cold. Without a perfectly executed insulation strategy, the home can become unbearably hot or cold and suffer from severe condensation on the inside of the steel walls. This condensation leads to rust and mold, compromising the structure and air quality. Overcoming this challenge requires careful research, a sufficient budget allocation for high-quality insulation (like closed-cell spray foam), and ensuring a continuous thermal break between the interior and the exterior steel shell. This is not an area to cut corners.

Can I build a container home by myself?

It is possible for a highly skilled and motivated DIYer to handle significant portions of a container home build, such as interior framing, insulation installation, and finishing work. However, it is highly discouraged to attempt the entire project alone, especially the critical structural components. Tasks like cutting large openings in the steel walls, welding containers together, placing the containers on the foundation with a crane, and all electrical and plumbing work require specialized skills, tools, and certifications. For safety, structural integrity, and compliance with building codes, it is essential to hire licensed professionals for site preparation, foundation work, structural modifications, and utility connections.

How do I find land for a container home?

Finding suitable land follows the same process as for a traditional home but with extra considerations. You can search through real estate websites, land auction sites, and work with a local realtor. The critical extra step is to thoroughly investigate the zoning laws and building codes of any parcel you are considering. You must confirm that the local jurisdiction allows residential use and, specifically, that there are no prohibitions against using shipping containers as a primary structural material. Also, consider the cost of developing the land: factors like slope, soil type (for septic and foundation), and access to utilities (or suitability for off-grid systems) will significantly impact your total budget.