What Makes a low cost shipping container home Truly Affordable and Durable?

Balancing Purchase Price, Condition, and Structural Modifications

A genuinely affordable container build is not simply the least expensive invoice you can obtain for steel boxes; it is the best balance between initial price, condition, and the volume of alterations you need to make later. A used container with visible dents, floor delamination, or door misalignment might seem like a bargain, yet every structural defect you accept at the beginning becomes a hidden line item in welding, framing, waterproofing, and time. A practical approach is to decide on the number of openings before buying and then choose containers that minimize cutting in those areas. Fewer cuts mean fewer reinforcements and fewer thermal bridges, which in turn improves energy performance and lowers both upfront and long-term costs. When people talk about a low cost shipping container home, they are really talking about limiting rework as much as limiting cash outlay today.

Cost Drivers You Can Control from Day One

- Openings and Cutouts: Each large window or sliding door requires structural framing and flashing; plan clusters of openings on the same side to simplify detailing.

- Foundation Type: Piers, screw piles, or a slender slab will carry different labor and inspection requirements; placing containers on adjustable piers can reduce excavation costs.

- Insulation Strategy: Exterior continuous insulation is typically superior for thermal performance and condensation control, but interior batt or spray foam may be cheaper in mild climates.

- Local Codes and Permits: Early contact with the authority having jurisdiction avoids redesign, resubmittals, and schedule slip that quietly increases cost.

- Logistics: Crane time, trucking distance, and site access (tight alleys, overhead wires) can swing the budget more than many first-time builders expect.

Comparing Container Builds to Other Small-House Options

For many buyers, the container path competes with small timber tiny homes and modular cabins. The container’s advantage is speed of enclosure and inherent durability, while wood frames can be easier to insulate and modify. The right choice depends on design appetite, climate, and skill set. The “affordable” result is not universal; it is the match between method and project conditions.

| Aspect | Container House | Wood Tiny House | Modular Cabin |

|---|---|---|---|

| Structure Speed | Fast enclosure once set | Moderate; framing on site | Fast; arrives prebuilt |

| Thermal Detailing | Requires thermal bridge strategy | Conventional and familiar | Factory-optimized |

| Change Flexibility | Cutting steel adds cost | Easy to modify | Limited after production |

| Durability | Excellent shell longevity | Depends on maintenance | Good; varies by spec |

| Typical Budget Risk | Logistics & insulation | Labor & weather delays | Change orders/transport |

Key Takeaway

If your site has straightforward access and your climate strategy is planned up front, a low cost shipping container home can minimize rework and hold its value, particularly when structural cuts are limited and mechanical systems are preplanned.

Designing cheap container house plans: Layouts, Structure, and Cost Control

Site-Responsive Layouts that Cut Waste

Design is the quiet engine of affordability. Thoughtful orientation, compact plumbing cores, and stacking wet rooms back-to-back reduce pipe runs and labor hours. A rectangular plan aligned with container geometry avoids awkward infill framing and odd angles that require custom trim. In practice, you can start with a single 40-foot unit and divide it into zones—sleep, service, and social—so that heating and cooling loads are predictable and ducts stay short. This is the essence of cheap container house plans: letting the container’s dimensions drive your simplicity rather than fighting them with complex forms.

Openings, Daylight, and Structure

Daylight is critical in narrow spaces, but every cut in the corrugated shell is a structural and thermal question. Group windows near corners or in a ribbon along one side to allow a single reinforcement strategy. Consider a clerestory bump-out made of light framing if you need taller glazing; it can provide sun without heavy steel work. When you do cut, brace the opening with rectangular hollow section or angle members, and always specify proper flashing and drainage planes to prevent concealed corrosion.

Room Modules and Furniture that Double as Structure

- Central Service Spine: Stack kitchen, bath, and laundry to share drains and vents.

- Flexible Partitioning: Use demountable panels to adapt rooms without new steel cuts.

- Built-In Storage: Toe-kick drawers, stair storage, and bed platforms reclaim volume.

- Sliding & Pocket Doors: Reduce clearance conflicts and make tight rooms usable.

Plan Types and Budget Effects

Design choices translate directly into dollars. A single-container studio is inherently simpler than a two-container wide plan that requires stitching, welding, and a larger roof plane. Yet, for families, the wider plan might avoid future add-ons and thus be cheaper over the life of the home. Choosing among plan types is a strategic decision, not merely a drawing preference.

| Plan Type | Pros | Cons | Budget Consideration |

|---|---|---|---|

| Single 40' Studio | Few cuts, simple systems | Tighter storage, less privacy | Lowest initial cost |

| Two 40' Side-by-Side | Wider living, better furniture fits | Roof seam and stitch steel work | Moderate; added welding |

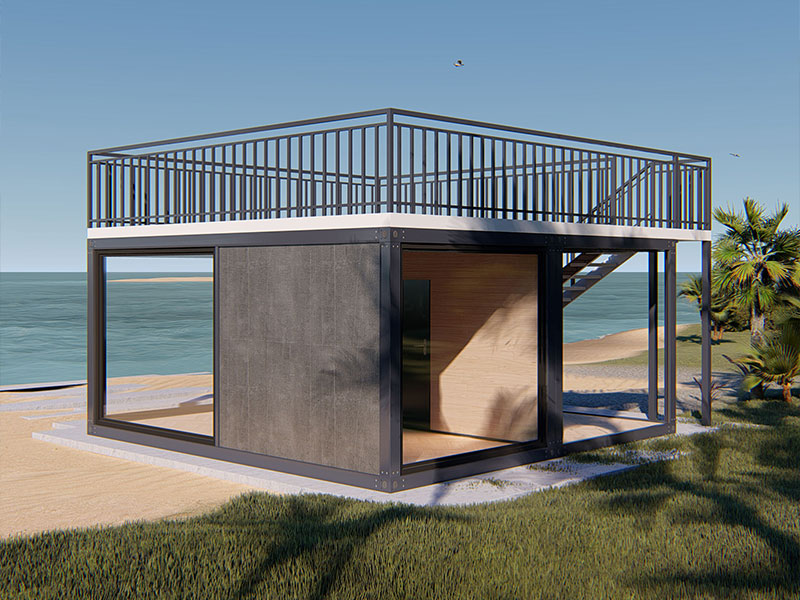

| Split-Level on Piers | Topography-friendly, views | Stairs and more detailing | Moderate to high; more framing |

| L-Shape 3 x 20' | Courtyard, cross-ventilation | Multiple corners to flash | Moderate; more corners |

Design Checklist

- Keep wet rooms contiguous to compress plumbing runs.

- Limit large openings; group them for simpler reinforcement.

- Decide early on interior vs exterior insulation to set framing depths.

- Align furniture to ridges and ribs to avoid wasted inches.

When your drawings respect the steel box, cheap container house plans become not only affordable but elegant in their restraint, cutting time on site and reducing the number of trades required.

Executing a DIY container home under 20k: Tools, Timeline, and Pitfalls

Budget Framing of the Build

Reaching the milestone of a DIY container home under 20k is ambitious but achievable for disciplined builders who self-perform labor, simplify the envelope, and phase “nice-to-haves” for later. The cornerstone is a staged budget that prioritizes weather-tightness and safety first, then finishes and upgrades. Many first-timers overbuy fixtures early while underestimating wiring, panel capacity, breakers, or the cost of basic site work like trenching. Instead, sequence cash toward the shell, doors, windows, and basic utilities, and purchase non-critical finishes after inspections pass.

Essential Tools and Skill Sets

- Metalwork: Angle grinder, welder (MIG for beginners), clamps, and safety gear.

- Carpentry: Circular saw, pocket-hole jig, square, and impact driver for fast framing.

- Weatherproofing: Butyl tape, flashing membrane, quality caulk, and rivet tools.

- MEP Basics: Multimeter, pex crimp tools, GFCI understanding, and basic code literacy.

DIY vs. Hiring: Where Saving Makes Sense

It is tempting to self-perform everything, but strategic outsourcing can keep a lean budget safer and on schedule. Cutting and reinforcing one large opening may be cheaper done by a local fabricator in a single day than stretched across several weekends of trial and error. Conversely, interior painting and cabinet assembly are excellent DIY tasks with minimal risk. The dividing line is liability: structural steel and main electrical connections carry consequences that dwarf their invoices if done incorrectly.

| Task | DIY Feasibility | When to Hire | Risk if Botched |

|---|---|---|---|

| Cutting Window Openings | Moderate with guidance | Complex or multi-opening walls | Warping, leaks, structural weakness |

| Main Electrical Service | Low (for novices) | Always recommended | Fire, code violations |

| Interior Framing | High | Unusual spans/curves | Out-of-square rooms, creaks |

| Waterproofing/Flashing | Moderate | Complex junctions/roof seams | Hidden rot, corrosion |

Lean Timeline for a Sub-$20k Build

- Week 1–2: Site prep, piers or screw piles, delivery logistics.

- Week 3: Container placement, initial cutouts, temporary weather protection.

- Week 4–5: Reinforcement, doors/windows installed to dry-in.

- Week 6–7: Electrical rough-in, plumbing rough, inspections.

- Week 8–9: Insulation and interior cladding.

- Week 10–12: Cabinets, fixtures, trim, punch list.

Cost Discipline Tips

- Standardize window sizes to reduce custom flashing and ordering delays.

- Use a single flooring type throughout to minimize transitions and waste.

- Build a compact mechanical closet to shorten ducting and piping.

With these controls, the phrase DIY container home under 20k becomes realistic, especially when you keep finishes simple, leverage reclaimed interior materials carefully, and stay ruthless about scope creep.

Engineering an off grid container cabin cheap: Power, Water, and Climate

Power Systems That Scale

Going off-grid can quickly inflate budgets unless systems are right-sized and modular. Start with a base solar array and battery bank sized for essential loads—lighting, refrigeration, device charging—and add inverters or panels later for luxury loads like induction cooking or mini-split heating. A small, efficient backup generator can protect batteries on overcast stretches without oversizing the entire array. The goal of an off grid container cabin cheap is to meet needs without paying for rarely used capacity.

Water Sourcing and Treatment

- Rainwater Harvesting: Metal roofs on containers are ideal catchment surfaces; add first-flush diverters and sediment filters before storage.

- Well or Delivered Water: Design plumbing to accept both with simple valving.

- Treatment: Use staged filtration (sediment → carbon → UV) to protect fixtures and health while keeping cartridge costs predictable.

Heat, Cooling, and Moisture Management

Steel shells are unforgiving with condensation, so assemblies must manage vapor pathways. In cold climates, interior spray foam provides an air and vapor barrier in one step, while in warm humid regions, continuous exterior insulation can reduce dew-point risks at the steel face. Cross-ventilation and a small ERV help purge moisture, especially after showers or cooking. For heat, compact high-efficiency heaters or mini-split heat pumps deliver control at low loads; wood stoves can work in rural settings if clearances and fresh air are handled.

Off-Grid Components and Budget Impact

| Component | Entry-Level Choice | Scalable Upgrade Path | Budget Effect |

|---|---|---|---|

| Solar Array | Modest wattage for essentials | Add parallel strings later | Lower upfront, staged costs |

| Batteries | Small LiFePO4 bank | Expandable rack units | Pay as you grow |

| Water | Rainwater + basic filters | UV + higher-capacity storage | Low with predictable consumables |

| HVAC | Single-zone mini-split | Multi-zone or backup heat | Moderate; efficient runtime |

Field-Proven Practices

- Design a “dark start” mode where essential circuits run without high-surge loads.

- Shade west-facing steel with awnings or vegetation to reduce late-day gains.

- Vent roof cavities to prevent heat buildup above insulated ceilings.

When systems are scaled to actual behavior instead of hypothetical extremes, an off grid container cabin cheap is not only feasible but comfortable year-round with simple maintenance routines.

Finishing a shipping container tiny house budget: Interiors, Storage, and Resale Value

Interior Materials that Stretch Dollars

Interior choices make or break perceived quality. In compact volumes, visual continuity matters more than expensive finishes. One durable floor type and a consistent wall surface produce calm and make spaces feel larger. Choose moisture-tolerant materials near baths and kitchens, and reserve accent materials for high-touch points like counters or stair treads. The objective is to deliver a polished feel within a strict shipping container tiny house budget by concentrating funds where hands and eyes linger.

Storage and Built-Ins that Add Value

- Platform Beds with Deep Drawers: Turn under-bed voids into seasonal storage.

- Full-Height Pantry Pull-Outs: Use the narrow container width to your advantage.

- Overhead Cubbies at Doorways: Capture space above swing paths.

- Fold-Down Desks/Dining: Multi-use furniture prevents clutter.

Lighting, Acoustics, and Comfort

Layered lighting (ambient, task, accent) prevents shadows in narrow rooms. Acoustic panels or soft surfaces on strategic walls cut reverberation, especially if you maintain some exposed steel. Small ceiling fans improve comfort at low energy cost and can reduce HVAC runtime. With attention to these details, a compact container home lives far larger than its footprint suggests.

Interior Choices and Budget Trade-Offs

| Category | Economical Choice | Premium Choice | Impact on Space/Value |

|---|---|---|---|

| Flooring | Durable click vinyl | Engineered hardwood | Economical is water-safe; premium adds resale appeal |

| Wall Finish | Plywood or drywall | Wood slats/veneer | Premium warms tone but costs more labor |

| Cabinetry | Flat-pack modules | Custom built-ins | Custom maximizes inches, higher upfront |

| Countertops | Laminates | Solid surface | Premium durable; economy stretches budget |

Resale Considerations

- Document permits and inspections; buyers pay a premium for verified compliance.

- Offer flexible furniture layouts in your marketing materials.

- Provide energy-use records to prove low operating costs.

By prioritizing durable, cohesive finishes and versatile storage, you protect your shipping container tiny house budget while elevating daily comfort and long-term value.

Quick Reference: From Plans to Move-In for a low cost shipping container home

Phase-by-Phase Milestones and What to Watch

- Assessment: Verify zoning, setbacks, and allowable foundation types.

- Planning: Produce concise drawings reflecting cheap container house plans with grouped wet rooms.

- Procurement: Choose containers minimizing cuts; schedule delivery and crane in one window.

- Shell: Place, cut, reinforce, and dry-in.

- MEP: Rough-in compact systems; test before insulation.

- Envelope: Execute your chosen insulation/vapor strategy without shortcuts.

- Interior: Install continuous flooring, simple trim, and space-saving built-ins.

- Systems: If off-grid, stage solar and water upgrades to keep an off grid container cabin cheap.

- Handover: Create a maintenance log and parts list for future owners.

Key Takeaways for Budget Container Living

Affordability is a design system and a construction behavior—not just a low sticker price. Choose containers that fit your openings strategy, keep plans geometry-friendly, outsource high-liability tasks, and stage upgrades. If you apply these principles, achieving a DIY container home under 20k or sustaining a comfortable off grid container cabin cheap becomes practical. Most importantly, treat insulation, waterproofing, and ventilation as investments that protect every other dollar you spend. That is how a low cost shipping container home stays economical for years, and how thoughtful cheap container house plans become the blueprint for lasting comfort within a strict shipping container tiny house budget.