In the modern era of modular construction, the Prefab Folding Container House has emerged as a pinnacle of logistics-oriented engineering. Unlike traditional modular buildings that require significant onsite assembly, the folding container home design allows for a fully integrated structure to be compressed for transport and expanded within minutes upon arrival. This innovation addresses the growing global demand for rapid-response infrastructure, sustainable housing, and cost-effective site offices. By leveraging high-tensile galvanized steel and advanced thermal insulation composites, a Prefab Folding Container House offers a robust alternative to permanent structures without compromising safety or comfort.

1. Structural Mechanics and Load-Bearing Capacity

The primary engineering challenge of a folding structure is maintaining rigid structural integrity while incorporating mechanical hinges. A high-quality Prefab Folding Container House utilizes a specialized "box-type" frame where the hinges are precisely engineered to lock into place, creating a stable load-bearing column system. Compared to standard flat-pack containers, the folding variant significantly reduces the complexity of on-site mechanical fastening. The roof and floor systems are pre-connected via high-strength pivots, ensuring that the lateral wind resistance and vertical snow load capacity meet international building codes. When analyzing folding container home durability in extreme weather, the interlocking seam technology plays a vital role in preventing water ingress and structural fatigue during high-wind events.

Comparison: Folding vs. Flat-Pack Container Structures

While both systems are modular, the folding mechanism offers superior deployment speed, whereas flat-packs typically offer more flexibility in internal layout customization.

| Feature | Folding Container House | Standard Flat-Pack Container |

| Deployment Time | 4-10 minutes (with crane) | 2-4 hours (manual assembly) |

| Logistics Efficiency | High (10-12 units per 40ft HQ) | Moderate (4-6 units per 40ft HQ) |

| Structural Rigidity | Integrated Hinge-Lock System | Bolted Corner Post System |

2. Thermal Performance and Energy Efficiency

Modern Prefab Folding Container House units are no longer simple metal boxes; they are thermal envelopes designed for energy conservation. Engineers typically utilize sandwich panels with Rockwool, EPS, or PU cores to achieve specific R-values (thermal resistance). The thickness of these panels, usually ranging from 50mm to 100mm, is calculated based on the climate zone of deployment. Compared to traditional brick-and-mortar construction, the thermal insulation of folding container homes is often more consistent because the panels are manufactured in controlled factory environments, eliminating thermal bridges caused by poor onsite workmanship. This makes them a preferred choice for modular disaster relief housing in both arctic and tropical regions.

Comparison: Insulation Material Efficiency

The choice of core material directly affects fire safety ratings and thermal conductivity (K-value).

| Core Material | Thermal Conductivity (W/m·K) | Fire Resistance Rating |

| EPS (Polystyrene) | 0.035 - 0.040 | B2 (Combustible) |

| Rockwool | 0.038 - 0.045 | A1 (Non-combustible) |

| Polyurethane (PU) | 0.022 - 0.028 | B1 (Flame Retardant) |

3. Logistics Optimization and Economic Impact

One of the most compelling arguments for adopting this technology is the reduction in the cost of transporting container homes related to transportation. A standard shipping container can only transport one or two pre-assembled units, but a Prefab Folding Container House can be collapsed to a height of approximately 40cm to 50cm. This allows for a "collapsed stack" of 10 to 12 units to be shipped in a single 40ft high-cube shipping container. Furthermore, the rapid deployment of folding container houses reduces onsite labor costs by up to 80%, as the unit is 90% pre-fitted with electrical wiring, flooring, and windows at the factory.

4. Customization and Functional Versatility

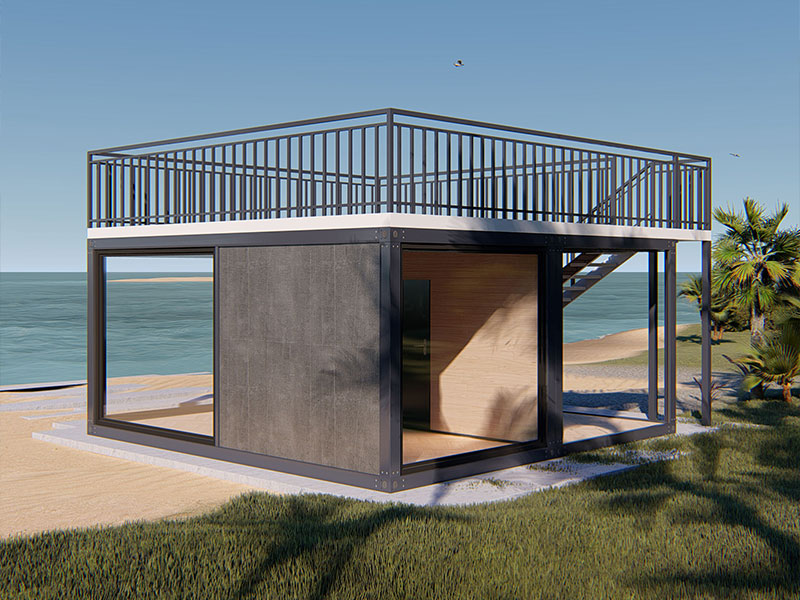

From an architectural perspective, the versatility of these units allows for various configurations. Whether used as portable site offices for construction or temporary foldable container dormitories for workers, the internal space can be partitioned to include kitchenettes, bathrooms, and living quarters. Advanced Prefab Folding Container House models even support stacking up to two levels, provided that the base unit is equipped with reinforced corner castings. This modularity is essential for urban infill projects where land area is limited but temporary high-density housing is required.

- Standard Dimensions: Typically 20ft (5.8m x 2.45m x 2.5m expanded).

- Internal Finishing: Fireproof MGO board flooring or luxury vinyl planks.

- Electrical Systems: Pre-installed according to CE, AS/NZS, or UL standards.

- Exterior Protection: High-grade automotive paint for anti-corrosion (C3 or C4 rating).

5. Sustainable Construction and Lifecycle Analysis

Sustainability is inherent in the Prefab Folding Container House lifecycle. By using recyclable steel and minimizing onsite waste, these structures have a significantly lower carbon footprint than traditional concrete buildings. If a project is finished, the reusable folding container units can be collapsed and moved to a new site, extending the product's lifespan to over 15-20 years. This "circular" approach to construction is becoming a cornerstone of environmental ESG (Environmental, Social, and Governance) policies for major developers worldwide.

Frequently Asked Questions (FAQ)

1. How long does it take to set up a Prefab Folding Container House?

On average, a team of two people and a light crane can expand a single unit in under 10 minutes. Final bolt-tightening and sealing usually take an additional 30 minutes before the unit is ready for move-in.

2. What is the expected folding container home durability in extreme weather?

These units are typically engineered to withstand wind speeds of up to 100-110 km/h and a floor load of 250kg/m². For areas with heavy snow, reinforced roof panels are recommended.

3. Are these units suitable for long-term portable site offices for construction?

Yes, because of their galvanized steel frame and anti-corrosive coating, they are highly resistant to the harsh environments of construction sites and can be moved multiple times without structural degradation.

4. How is the folding container home cost compared to traditional housing?

In terms of initial capital expenditure, folding containers can be 30% to 50% cheaper. The biggest savings, however, come from the reduction in foundation work, labor, and transportation fees.

5. Can I combine units to create a large-scale modular disaster relief housing camp?

Absolutely. Multiple reusable folding container units can be joined side-by-side or stacked (with proper reinforcement) to create medical clinics, dining halls, or large-scale emergency shelters.

Industry References

- ISO 1161:2016 - Series 1 freight containers — Corner and intermediate fittings.

- ASTM E2126 - Standard Test Methods for Cyclic (Reversed) Load Test for Shear Resistance.

- Modular Building Institute (MBI) - Guidelines for Relocatable Buildings.

- Standard for Fire Safety in Modular Construction (NFPA 285).