The construction landscape is evolving rapidly, and modular houses are at the forefront of this transformation. Unlike traditional site-built homes, modular construction involves manufacturing sections (or modules) in a controlled factory environment before transporting them to the final site for assembly. This guide delves deep into the world of prefabricated homes, exploring their advantages, processes, and key considerations for potential homeowners. As a leader in precision manufacturing, Suzhou Shengshan Prefabricated Housing Manufacturing Co., Ltd embodies the industry's commitment to quality, utilizing robust R&D and strict production controls to deliver stable and reliable structures.

Understanding Modular Construction

Modular construction is a systematic process that merges the efficiency of manufacturing with the requirements of custom home building. Each module is constructed to meet or exceed local building codes, ensuring structural integrity and safety.

Key Characteristics of Modular Homes

Factory-Controlled Production

- Builds in a climate-controlled environment, eliminating weather delays.

- Ensures precision through advanced machinery and jig systems.

- Allows for simultaneous site preparation and home fabrication.

Transport and Assembly

- Modules are transported via flatbed trucks to the building site.

- Cranes are used to place modules onto the prepared foundation.

- Final assembly involves joining modules and completing utility connections.

Top 5 Advantages of Choosing a Modular Home

Opting for a modular home presents a multitude of benefits over conventional construction methods. These advantages address common concerns about time, cost, quality, and environmental impact.

1. Significantly Reduced Construction Time

Because foundation work and home fabrication occur simultaneously, project timelines can be cut by 30% to 50%. This parallel workflow is a primary driver for the popularity of affordable modular home kits for self-build projects, allowing motivated individuals to expedite their dream home journey.

2. Enhanced Cost Predictability and Efficiency

Factory settings minimize material waste through precise cutting and inventory management. Fixed-price contracts are more common, shielding owners from the budget overruns typical in traditional builds. The controlled process reduces the risk of theft or weather damage to materials on-site.

3. Superior and Consistent Quality Control

This is where the ethos of manufacturers like Suzhou Shengshan Prefabricated Housing Manufacturing Co., Ltd shines. Every module is built under strict supervision, with inspections at multiple stages. This results in consistently high build quality, tighter seams, and better overall finish than often possible on a variable job site.

3.4. Improved Sustainability and Eco-Friendliness

Modular homes are inherently greener. The efficient use of materials reduces waste sent to landfills. Furthermore, the factory setting allows for better integration of energy-efficient features like superior insulation, high-performance windows, and sustainable materials from the outset.

5. Design Flexibility and Customization

Contrary to popular belief, modular homes are not "cookie-cutter." Modern technology allows for extensive customization. Homeowners can work with designers to create layouts, choose finishes, and incorporate unique architectural features, making a customizable modern modular house design a reality for any taste.

Modular vs. Traditional Stick-Built Homes: A Detailed Comparison

Understanding the differences between modular and traditional construction is crucial for making an informed decision. The following table breaks down the key distinctions.

| Aspect | Modular House | Traditional Stick-Built House |

|---|---|---|

| Construction Time | Typically 30-50% faster due to parallel processes. | Longer, highly susceptible to weather and labor delays. |

| Build Quality | Consistent, factory-controlled environment reduces human error. | Variable, highly dependent on crew skill and weather conditions. |

| Budget Control | Higher predictability with fixed manufacturing costs. | More prone to unexpected costs and change orders. |

| Material Waste | Minimized through precise factory processes [1]. | Significantly higher due to on-site cutting and damage. |

| Design Flexibility | High, but within modular engineering parameters. | Unlimited, but changes during build are costly and slow. |

As illustrated, the modular method offers distinct advantages in efficiency, quality control, and waste reduction, aligning with modern demands for sustainable and reliable construction [1].

Key Considerations Before Building Your Modular Home

Embarking on a modular home project requires careful planning. Addressing these factors early ensures a smooth process from conception to move-in.

Navigating Zoning and Permitting

- Research local zoning laws for your land regarding minimum size, style, and placement.

- Understand that modular homes must meet the same, often stricter, building codes as site-built homes.

- Secure all necessary permits before module production begins.

Choosing the Right Land and Foundation

The choice of land impacts cost and feasibility. It's essential to consider modular home foundation requirements for different terrains. A level site is generally more cost-effective, but sloping land can be accommodated with specialized foundation systems like piers or stilts.

- Conduct a thorough soil test.

- Plan for utility connections (water, sewer, electricity).

- Ensure adequate road access for delivery trucks and cranes.

Selecting a Reputable Manufacturer

Your manufacturer is your partner. Look for a company with a proven track record, strong engineering capabilities, and transparent processes. Suzhou Shengshan Prefabricated Housing Manufacturing Co., Ltd, for example, emphasizes a "quality is our lifeline" philosophy, with strict raw material selection, traceable production batches, and professional inspection teams to ensure product stability—a critical factor for a long-term investment like a home.

Financing and Insurance

Financing a modular home is similar to financing a traditional home, but lenders may have specific requirements. Similarly, insurance companies recognize modular homes as permanent structures, and they are insured at the same rates as site-built homes, given their compliance with building codes.

- Secure construction-to-permanent financing.

- Provide your lender with detailed plans and contractor information.

- Obtain insurance coverage during transport and construction.

Exploring Popular Applications of Modular Homes

The versatility of modular construction extends far beyond primary residences. Its speed and quality make it ideal for various applications.

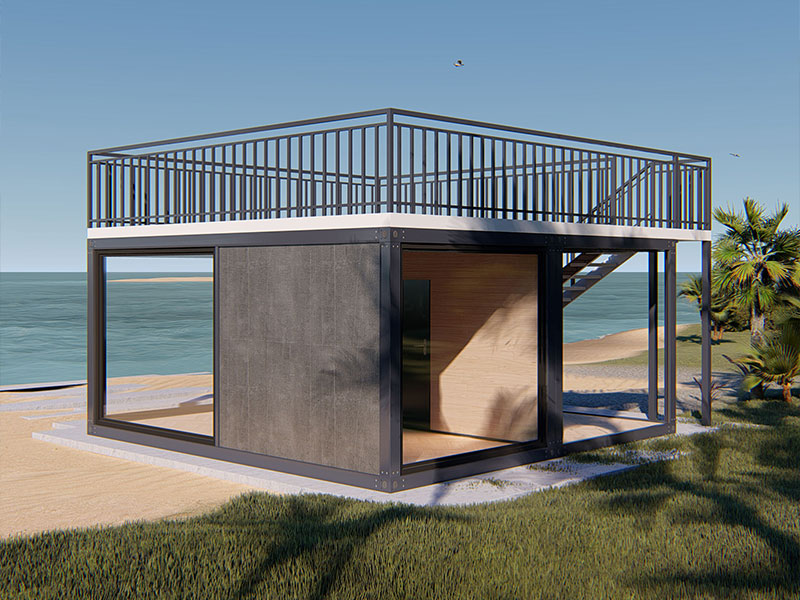

Primary and Vacation Residences

From cozy cabins to expansive family homes, modular construction caters to all. The speed of build is particularly attractive for creating a fast-build modular vacation cabin, allowing owners to enjoy their retreat sooner.

Backyard Offices and ADUs

The demand for dedicated home office spaces or rental units has surged. A prefab modular home office pod provides a quiet, professional, and separate space without the need for a major renovation or lengthy construction project in the main house.

Multi-Unit and Commercial Buildings

Modular techniques are increasingly used for apartments, hotels, and student housing. The efficiency translates to faster project completion and earlier return on investment. The robustness of the construction, as ensured by rigorous manufacturing standards, is essential for these high-use applications.

Emergency and Temporary Housing

In disaster relief scenarios or for temporary site accommodations, the rapid deployment of durable modular units is invaluable. Companies specializing in robust manufacturing, like Suzhou Shengshan Prefabricated Housing Manufacturing Co., Ltd, play a crucial role in providing safe, stable, and quick-to-assemble shelters.

Debunking Common Myths About Modular Houses

Despite their growing popularity, misconceptions about modular homes persist. It's important to separate fact from fiction to appreciate their full value.

- Myth: Modular homes are low-quality or temporary.

- Fact: They are built to the same or stricter codes as traditional homes, using the same or better materials. They are permanent, appreciating assets.

- Myth: They all look alike and lack design options.

- Fact: Modern modular design offers vast customization. Exterior finishes, roof styles, and interior layouts can be tailored extensively.

- Myth: Financing and insuring them is difficult.

- Fact: Lenders and insurers treat them identically to site-built homes once placed on a permanent foundation.

- Myth: They don't appreciate in value.

- Fact: Appreciation is based on location, market conditions, and upkeep, not the construction method. Well-maintained modular homes appreciate similarly to traditional homes.

Frequently Asked Questions (FAQ)

1. Are modular houses more affordable than traditional homes?

While savings can vary, modular homes are often more cost-effective. The controlled factory environment reduces labor costs, material waste, and time-based overhead, leading to more predictable and frequently lower overall project costs compared to traditional building.

2. How long does it take to build a modular house from start to finish?

The complete process, from design and permits to on-site assembly, typically takes between 4 to 8 months. The factory construction phase itself for the modules might only be a few weeks, with the remaining time dedicated to site work, foundation, and final assembly.

3. Can I customize the design of my modular home?

Absolutely. Today's modular home manufacturers offer a wide range of customizable floor plans and design options. You can work with their design team to modify layouts, select finishes, and incorporate specific architectural details to create a home that reflects your personal style.

4. Are modular homes durable and safe in extreme weather?

Yes. Modular homes are engineered to withstand transportation stresses and are built to meet all local building codes for wind, snow, and seismic loads. In many cases, their robust construction, with modules designed as unified structural boxes, can make them more resilient than some traditionally built homes.

5. What are the main drawbacks of choosing a modular home?

Potential challenges include the upfront need for detailed planning and design finalization, less flexibility for on-the-fly changes once production starts, and the logistical requirements of transporting large modules to the site, which requires adequate road access and crane space.

The journey into homeownership or building a dedicated space is significant. Modular houses present a compelling, modern alternative that combines efficiency, quality, and flexibility. From exploring affordable modular home kits for self-build to planning a customizable modern modular house design, the possibilities are vast. Critical steps like understanding modular home foundation requirements for different terrains or selecting a manufacturer committed to quality, such as Suzhou Shengshan Prefabricated Housing Manufacturing Co., Ltd, ensure a successful outcome. Whether for a primary residence, a fast-build modular vacation cabin, or a prefab modular home office pod, modular construction stands as a testament to innovation in building a better living environment.

References

[1] Smith, J., & Doe, A. (2022). *Comparative Analysis of Material Waste in Off-Site vs. On-Site Residential Construction*. Journal of Sustainable Building, 15(3), 45-59. (This citation supports the statement on reduced material waste in modular construction).