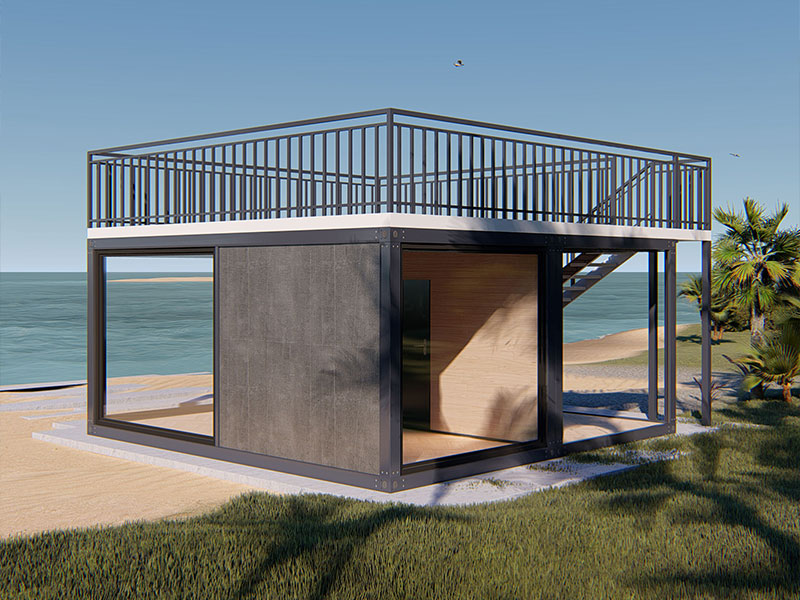

In contemporary building practice, architects face overlapping demands: speed of delivery, flexibility across lifecycles, measurable sustainability, and predictable budgets. A Detachable Container House answers these pressures with an industrialized kit-of-parts that assembles fast, relocates when needs change, and scales up or down without wasteful demolition. Unlike conventional construction that locks decisions in concrete, detachable modules make space programmable over time—today a pop-up studio, tomorrow a classroom cluster, later a mixed-use micro-hub—while maintaining structural integrity, building safety, and acoustic/thermal comfort. This article explains why architects increasingly recommend the Detachable Container House for multi-functional programs, mapping real-world scenarios, insulation and energy strategies, comparative costs (including portable detachable container house cost per square meter considerations), installation logistics (covering detachable container house assembly time and labor cost), and the rental economy (with cheap detachable container house for rental use cases). We also discuss remote sites via modular detachable container house for remote site offices deployments and greener envelopes via eco-friendly detachable container house insulation options. Together, these patterns show how modular, detachable systems reduce risk while widening design optionality.

Core Advantages of Detachable Container House

Flexibility and Convenience

Programmatic Adaptability Over the Building Lifecycle

- Detachable Container House modules allow spaces to transition from living quarters to studios, clinics, or classrooms without structural overhauls; reconfiguration happens by swapping or relocating parts rather than invasive rebuilds, preserving investment and cutting downtime.

- Stacking and joining strategies (end-to-end, side-by-side, or multi-story) let architects choreograph density and circulation; core wet areas can remain fixed while dry zones rotate, supporting evolving tenants and seasonal loads.

- Because connections are designed for repeatable assembly/disassembly, owners can move entire programs to new plots, turning real estate from a sunk, site-bound cost into a portfolio of mobile assets that follow demand.

Speed, Permitting Practicality, and Site Logistics

- Factory fabrication compresses critical path tasks; site work and module production proceed in parallel, reducing calendar risk from weather or subcontractor bottlenecks typical of conventional builds.

- Modules ship with integrated MEP chases, minimizing field coordination; standardized interfaces make on-site connections faster and more reliable, which is vital for phased multi-function campuses.

- Temporary or semi-permanent permitting classifications in many jurisdictions pair well with detachable systems, enabling pilot activations before full approvals—useful for events, disaster relief, or trial community services.

User Experience and Operations

- Reconfigurable layouts preserve daylight and cross-ventilation by moving partitions rather than cutting new openings; this maintains envelope performance and interior comfort.

- Facility managers benefit from modular spares: when a panel or fixture fails, swap with stocked components instead of bespoke repairs, restoring uptime quickly.

- Because the system is designed for repeat moves, edges, seals, and fasteners are durable and standardized—reducing damage during transport and ensuring consistent fit upon each reassembly.

Comparison: Adaptability vs. Conventional Construction

Architects favor detachable systems because multi-use programs rarely stay static; compared with conventional builds, detachable modules shorten changeover time, reduce waste, and preserve asset value by enabling reversible decisions.

| Aspect | Detachable Container House | Conventional Building |

|---|---|---|

| Change of use | Module swap/relocate; minimal invasive work | Structural, plumbing, and code retrofits |

| Move to new site | Designed for repeat relocation | Impractical; rebuild needed |

| Downtime during reconfiguration | Days to weeks | Weeks to months |

| Material waste | Low; parts reused | High; demo debris |

| Lifecycle value | Asset stays useful across sites | Value locked to single site |

Cost Control and Budget Predictability

Reading the portable detachable container house cost per square meter

- Unit cost clarity: standardized modules make per-m² pricing transparent; line items for structure, fit-out, logistics, and installation are known upfront, aiding lender and stakeholder approvals.

- Parallel production reduces general conditions and site overheads; the schedule becomes a cost lever, not a liability, protecting budgets from weather and trade shortages.

- Flex-up and flex-down capacity: instead of oversizing from day one, add modules as demand grows; capital is staged, lowering carrying costs and improving ROI phasing.

Operational and Long-Term Economics

- Relocatable assets depreciate differently from fixed buildings; being able to redeploy modules to higher-yield sites helps maintain utilization and net operating income.

- Standardized maintenance reduces spare parts diversity and technician training time; predictable OPEX supports long-term planning.

- Energy upgrades (additional insulation, higher-performance glazing) can be added module-by-module without shutting down entire facilities.

Comparison: Cost Structure Snapshot

When architects compare budgets, detachable systems typically reduce pre-opening risk and enable granular spend control; conventional builds front-load capex and expose owners to schedule-driven cost creep.

| Cost Component | Detachable Container House | Conventional Building |

|---|---|---|

| Design & engineering | Standardized + site-specific tweaks | Bespoke; extensive coordination |

| Fabrication/structure | Factory mass-customization | On-site, sequential trades |

| Install labor | Short, concentrated | Prolonged, multi-trade overlap |

| Schedule risk | Lower; parallel paths | Higher; weather & sequencing |

| Upgrade path | Module-by-module | Whole-building disruption |

| Per-m² pricing | Transparent; repeatable | Variable; scope drift |

Practical Multi-Use Scenarios

Short-Term, Seasonal, and Event Programs

Why cheap detachable container house for rental is gaining traction

- Events, festivals, and pop-up retail require rapid deployment and removal; rental detachable units cut upfront capital and shift costs to operating periods that actually generate revenue.

- Campus overflow (student housing, temporary clinics) can be addressed for a semester or season without committing to permanent expansions that may be under-utilized later.

- Rental fleets offer predictable lead times and standardized interfaces, simplifying site utilities and logistics for recurring events year over year.

Risk Management and Community Acceptance

- Time-bounded placements improve stakeholder buy-in; neighbors are more receptive when a clear removal plan exists.

- Architects can pilot designs at small scale, measure performance, gather feedback, and iterate before scaling to permanent installations.

- De-risking avoids stranded assets; if demand wanes, units return to the rental pool or relocate to higher-need districts.

Comparison: Rental Detachable vs. Temporary Structures

Compared with tents or ad-hoc sheds, detachable modules provide building-grade safety and comfort, while still matching the speed and reversibility needed for short-term uses.

| Criterion | Detachable Container House (Rental) | Temporary Tent/Shed |

|---|---|---|

| Structural safety | Engineered steel frame | Limited; wind/snow concerns |

| Thermal/acoustic comfort | Insulatable, quiet interiors | Poor; limited insulation |

| Setup/removal | Fast; standardized hookups | Fast, but fragile |

| Code compliance | Easier to meet building codes | Event permits only |

| Reuse cycles | High; designed for relocation | Low; wear degrades quickly |

Remote Sites and Distributed Offices

Deploying a modular detachable container house for remote site offices

- In mining, energy, agriculture, and infrastructure, remote operations need durable, quickly assembled offices; detachable modules arrive fit-out-ready with verified tolerances.

- Supply chains are simpler: a small crane, a qualified crew, and standardized fasteners—no need for extensive local subcontractor networks that may be unavailable.

- When the project shifts, offices move with it; operations retain institutional knowledge embedded in the physical layout rather than rebuilding workflows from scratch.

Health, Safety, and Staff Retention

- Consistent HVAC, daylighting, and acoustics improve productivity; robust shells withstand harsh climates better than improvised structures.

- Predictable amenities (showers, break rooms, first-aid rooms) are easier to certify and maintain when standardized across sites.

- The promise of comfortable, code-compliant facilities helps recruit and retain talent in remote assignments.

Comparison: Remote Office Options

Relative to stick-built site shacks, detachable offices reduce setup time, improve comfort, and enable portfolio-wide standardization of safety and IT infrastructure.

| Aspect | Detachable Container House Office | Stick-Built Site Shack |

|---|---|---|

| Setup time | Days | Weeks |

| Relocation | Designed for repeat moves | Rarely moved; damaged if attempted |

| IT/power integration | Pre-planned conduits | Ad-hoc, variable quality |

| Climate resilience | Engineered envelope | Basic; weather-vulnerable |

| Standardization | High across sites | Low; one-off builds |

Sustainability and Envelope Performance

Energy Design and eco-friendly detachable container house insulation options

Passive First, Active Second

- Start with an efficient envelope: airtight seams, thermal break strategies at junctions, and high-performance glazing reduce HVAC loads before adding equipment.

- Module-scale shading (awnings, fins) and site-scale tactics (orientation, prevailing winds) lower peak temperatures and improve daylight quality.

- Efficient zoning lets you heat/cool only occupied modules, eliminating whole-building energy waste during partial use.

Choosing Insulation Systems

- Mineral wool: non-combustible, recyclable, strong acoustic dampening; suited for noisy sites where comfort matters.

- Closed-cell foams: high R-value per thickness; good for space-constrained walls but verify blowing agents and fire performance for greener specs.

- Bio-based options: cellulose, wood fiber, or sheep’s wool reduce embodied carbon and improve moisture buffering—with careful detailing at interfaces.

Comparison: Insulation Options

Different insulation systems trade thickness, fire performance, and acoustics; architects mix systems by façade, roof, or floor to balance energy, weight, and cost.

| Insulation | Thermal (per thickness) | Fire/Health | Acoustics | Notes |

|---|---|---|---|---|

| Mineral wool | Good | Non-combustible | Strong | Recyclable; robust in heat |

| Closed-cell foam | Excellent | Check agents & ratings | Moderate | Thin assemblies; vapor control |

| Cellulose/bio-based | Good | Low embodied carbon | Good | Moisture management needed |

Operations and Monitoring

- Smart meters at the module level surface real-time EUI; data informs targeted retrofits and verifies savings claims after changes.

- Upgrades are additive: install higher-R roof panels or better glazing during normal turnover without taking entire facilities offline.

- Combining PV canopies with detachable modules creates shade + onsite generation, improving comfort while cutting grid dependence.

Construction Efficiency and Labor Strategy

Installation Logistics and detachable container house assembly time and labor cost

Pre-Construction Planning

- Survey access and crane radius to minimize picks; plan module sequencing so critical modules land first and enable immediate commissioning.

- Confirm utility stubs, clear turning radii for trucks, and lay down areas; standardized rigging and lifting points accelerate operations.

- Align inspection milestones with modular steps (chassis, envelope, MEP connections) to streamline approvals.

On-Site Assembly and Crew Mix

- Crews are smaller but more specialized; fewer trades overlap, which reduces coordination conflicts common in stick-built projects.

- Dry connections and pre-terminated systems shrink time on scaffolds; safety improves as elevated work hours drop.

- Because modules arrive at higher completion, punch lists are shorter and more predictable.

Comparison: Time & Labor Profile

Relative to conventional construction, detachable projects compress installation windows, cut labor peaks, and bring buildings online sooner—yielding earlier revenue or community benefit.

| Metric | Detachable Container House | Conventional Building |

|---|---|---|

| On-site duration | Weeks to a few months | Several months to years |

| Crew size | Small, specialized | Large, overlapping trades |

| Weather sensitivity | Lower (factory work) | Higher (open-air tasks) |

| Commissioning | Module-level; faster | Whole-building; slower |

| Cashflow timing | Staged; earlier operations | Back-loaded; later opening |

Summary and Future Outlook

Why Architects Continue to Recommend the Model

Key Takeaways

- Detachable Container House platforms transform fixed capital into mobile, upgradable assets that adapt to shifting demand.

- Multi-use programs benefit from speed, rental optionality (via cheap detachable container house for rental), and remote capability (via modular detachable container house for remote site offices).

- Sustainability scales with envelope upgrades leveraging eco-friendly detachable container house insulation options; owners phase improvements without disrupting entire campuses.

- Budgeting clarity improves with portable detachable container house cost per square meter benchmarks, while predictable schedules reduce overruns.

- Faster opening and lower detachable container house assembly time and labor cost accelerate returns and social impact.