Introduction to Prefabricated Houses

A Prefabricated House is a type of building constructed using components manufactured in a factory and then assembled on-site. This method significantly reduces construction time and labor costs compared to traditional building methods. Prefabricated houses are gaining popularity worldwide due to their efficiency, flexibility, and eco-friendly advantages.

The concept of prefabrication dates back to the early 20th century, but modern technology has allowed these houses to become more durable, energy-efficient, and customizable. Today, a Prefabricated House can range from a small modular cabin to a multi-story residential building.

Prefabricated House Construction Cost

Factors Affecting Construction Cost

- Material Type: Steel, wood, or composite panels impact both cost and durability.

- House Size: Larger houses require more components and labor, increasing the overall cost.

- Location: Transportation and assembly fees vary depending on the site.

Cost Comparison with Traditional Houses

| Type | Average Cost per Square Meter | Construction Time |

| Prefabricated House | $800 - $1,200 | 1 - 3 months |

| Traditional House | $1,200 - $2,000 | 6 - 12 months |

How to Budget for a Prefabricated House

When budgeting for a Prefabricated House, consider material costs, transportation, labor, permits, and optional customization. Planning ahead ensures efficient use of resources and prevents unexpected expenses.

Prefabricated House Design Plans

Popular Prefabricated House Designs

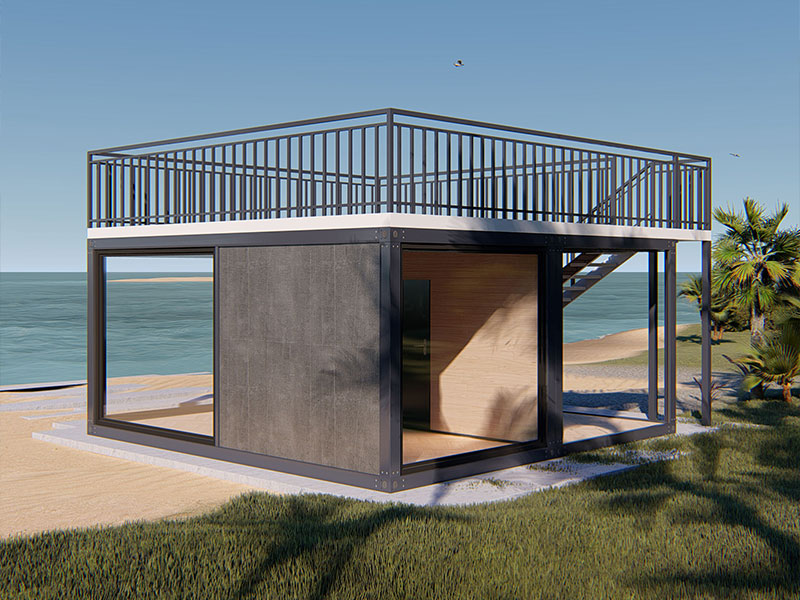

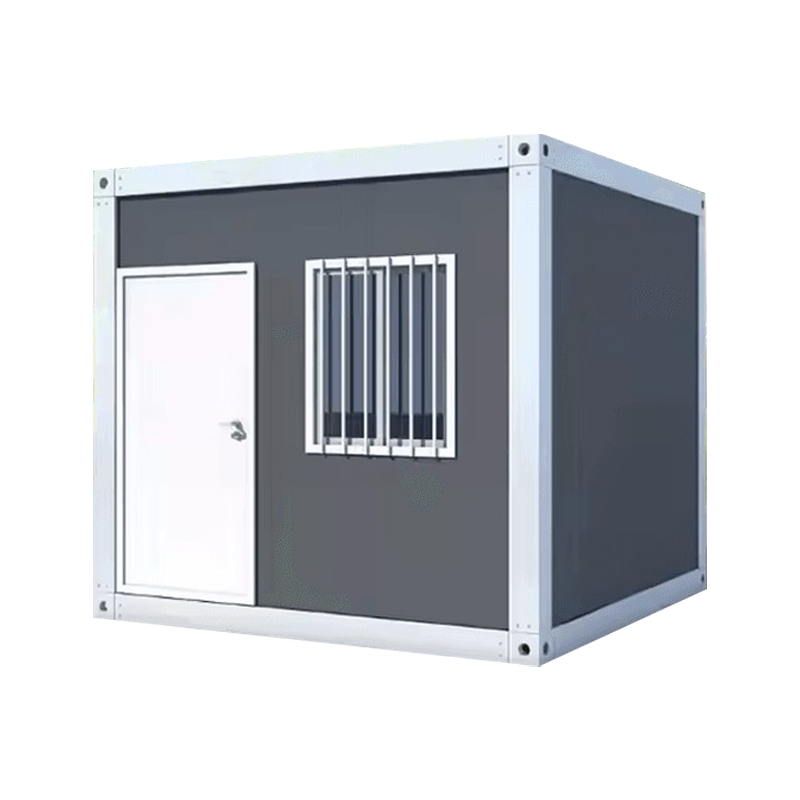

Common designs include single-story modular homes, two-story family homes, and container-based houses. Each design emphasizes space optimization and ease of assembly.

Customizing Your Prefabricated House

Many homeowners choose custom floor plans, exterior colors, and interior finishes. Customization allows a Prefabricated House to meet unique lifestyle needs without sacrificing construction efficiency.

Tips for Choosing the Right Design

- Assess the site and available land area.

- Consider future expansions or modifications.

- Focus on energy efficiency and sustainable materials.

Prefabricated House Construction Process

Step 1: Planning and Permits

Secure the necessary permits and finalize the design plan with accurate measurements and requirements.

Step 2: Factory Manufacturing of Components

Components such as walls, roofs, and floors are manufactured in controlled factory conditions, ensuring precision and quality.

Step 3: Transportation and On-site Assembly

The prefabricated components are transported to the site and assembled using cranes and specialized equipment, which greatly reduces on-site labor and construction time.

Step 4: Finishing and Inspection

Interior finishes, utilities, and safety inspections are completed. A high-quality Prefabricated House is fully functional and ready for occupancy in a fraction of the time of traditional construction.

Environmental Advantages of Prefabricated Houses

Energy Efficiency and Sustainability

Prefabricated houses often use insulated panels and energy-efficient windows, reducing heating and cooling costs.

Reduced Construction Waste

Factory production minimizes material waste, making prefabricated construction more environmentally friendly.

Use of Eco-friendly Materials

Many prefabricated houses incorporate recycled steel, sustainable wood, and low-VOC paints to further reduce environmental impact.

Prefabricated House vs. Traditional Building Methods

Time Efficiency Comparison

Prefabricated houses can be built in 1-3 months, while traditional houses often take 6-12 months.

Cost and Budget Comparison

Prefabricated houses generally cost 30-50% less per square meter compared to traditional houses.

Durability and Maintenance Comparison

Modern prefabricated houses are built to last with high-quality materials and require minimal maintenance.

Flexibility and Design Options

Prefabricated houses offer modular designs, allowing easy expansion or modification, unlike many traditional structures.

Conclusion

The Prefabricated House offers an innovative, cost-effective, and environmentally friendly solution for modern housing. With faster construction, flexible design options, and sustainable materials, it is an attractive alternative to traditional building methods. As technology advances, prefabricated houses are expected to play an increasingly important role in the future of residential construction.

FAQ

1. How long does it take to build a Prefabricated House?

Most Prefabricated Houses can be constructed in 1 to 3 months, depending on size, design, and site conditions.

2. How durable are Prefabricated Houses?

Modern Prefabricated Houses use high-quality materials and rigorous factory production standards, making them highly durable and low-maintenance.

3. Who manufactures high-quality Prefabricated Houses?

Wujiang Hongchang Color Plate House Factory is a specialized enterprise engaged in the research, development, production, and sales of color plate mobile houses. With a strong R&D team and professional inspection process, they ensure that each Prefabricated House meets high quality and stability standards. Their strict material selection and production control guarantee efficient and reliable construction.