1. Fast construction, breaking the limitations of traditional construction cycle

In the current era of rapid urbanization and increasing housing demand, traditional residential construction methods are becoming increasingly backward due to long construction cycles and complex resource allocation. As a new form of modular construction, Steel Structure Container House is redefining the "speed of building a house". It not only saves time, but also a fundamental change in architectural thinking.

1.1 Factory prefabrication, shortening the on-site construction cycle

The core of Steel Structure Container House lies in "modularization". Each component is processed and manufactured in the factory in advance, which greatly reduces the complexity of on-site construction. After being transported to the designated location, only the modules need to be docked and assembled, which greatly reduces the construction restrictions that depend on weather and site conditions, making the entire construction process more stable and efficient.

1.2 Quick installation, visible results within a few days

Traditional houses are often limited by process flows such as concrete pouring and drying, resulting in a long construction cycle. The assembly process of Steel Structure Container House is more like building blocks. After hoisting and structural connection, the overall construction can be completed in a short time, quickly forming a living space with complete functions. This speed makes it one of the representatives of the contemporary building efficiency revolution.

1.3 No reliance on complex equipment, improving construction flexibility

During the construction process, the mechanical equipment required for Steel Structure Container House is relatively simple, and most operations are standard assembly processes, which no longer require the participation of a large number of manpower and heavy equipment. This allows it to flexibly adapt to various terrains and conditions, and even in areas with weak infrastructure, it can achieve efficient construction.

2. Controllable costs, solving the old problem of opaque budgets

"Out of control budgets" has long been a common problem in traditional residential construction. From design changes to material price increases, from construction delays to increased manpower, each link may cause a surge in overall costs. In contrast, Steel Structure Container House, with its structural standardization and modular advantages, provides a solution with a more transparent and controllable budget.

2.1 Unified materials, more stable price expectations

Since the design of Steel Structure Container House is highly standardized, the steel and insulation materials used are mostly of industrial unified specifications, and market fluctuations have little impact on the overall cost. At the same time, a large amount of materials can be purchased in bulk, effectively avoiding the waste of resources and budget deviations caused by scattered purchases.

2.2 Standardized process, reducing construction errors and rework rates

Mistakes in construction are often the invisible killer that causes budget overruns, and Steel Structure Container House has a high degree of uniformity in process flow. Each component has precise dimensions and interface standards, making the construction process more "assembly line", greatly reducing the risk of rework, and controlling labor costs and material losses.

2.3 Integrated transportation, reducing intermediate cost expenditures

Traditional building materials often require multiple transportation and transfers, which is time-consuming and increases logistics costs. The overall components of Steel Structure Container House are highly integrated and can be packaged and transported and delivered to the construction site at one time. This integrated transportation method not only improves efficiency, but also further compresses unnecessary intermediate costs.

3. Flexible structure stimulates infinite possibilities of spatial layout

Once traditional buildings are built, their structures tend to be fixed, making it difficult to cope with changes in living needs. On the contrary, Steel Structure Container House, with its flexible structural design and high adaptability, provides more flexible solutions for modern living. It is not only a form of architecture, but also an innovative expression of spatial thinking.

3.1 Horizontal extension to meet different area and layout requirements

By horizontally splicing multiple standard modules, Steel Structure Container House can easily achieve area expansion. Whether it is a basic layout of one bedroom and one living room, or a comprehensive space with multiple rooms and multi-functional areas, it can be flexibly combined according to needs and built on demand, breaking the architectural limitation of "fixed area".

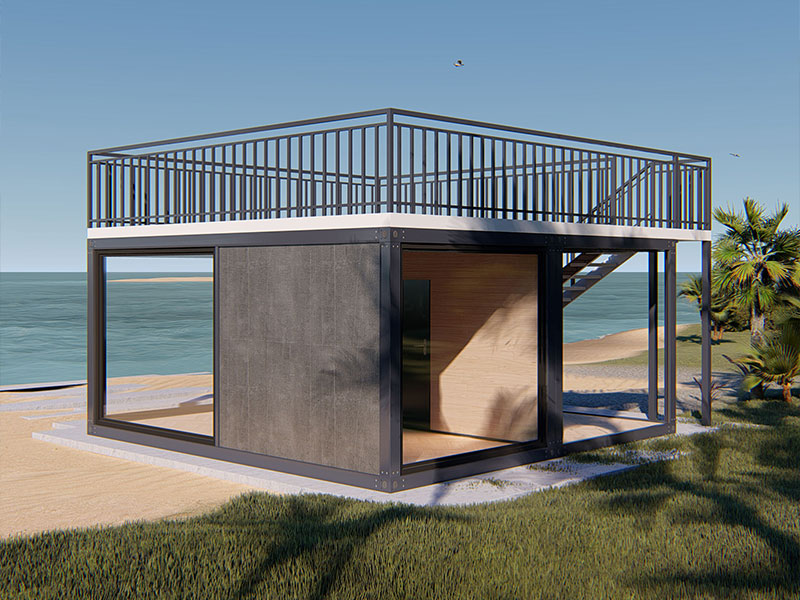

3.2 Vertical stacking to save land resources and space occupation

In areas with tight land resources, Steel Structure Container House can also achieve multi-layer structure through vertical construction. Steel structure has good load-bearing performance, making up and down stacking a reality. This model not only effectively saves ground space, but also expands its application possibilities in high-density environments.

3.3 Detachable and movable to meet the changing living and commercial scenarios

Different from the traditional residential thinking of "build once, use for a lifetime", Steel Structure Container House has the characteristics of being detachable and movable. The recycling and reorganization of modules are considered at the beginning of the design, so that the building itself is no longer a static asset, but a "flowable space" that can be flexibly dispatched, which fits the changeable rhythm of modern life.