1. Material advancement: the leap from masonry to technological panels

1.1 Rejecting heaviness and bulkiness, moving towards lightness and efficiency

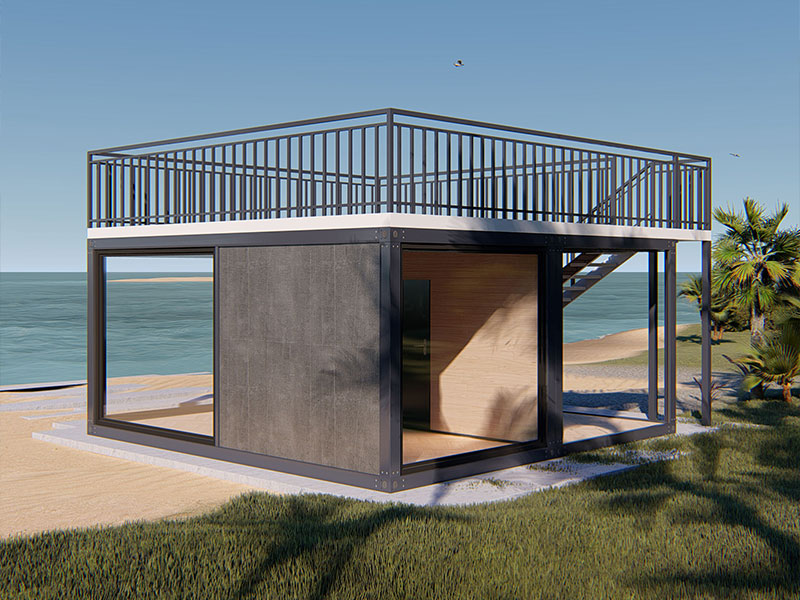

In the traditional construction model, masonry, reinforced concrete and other materials have always been the core structural carriers, but this "heaviness" not only brings inconvenience in transportation and construction, but also greatly limits the flexibility of the structure. The emergence of Sandwich Panel Container House has completely broken this shackle. It adopts a lightweight and high-strength sandwich panel structure to maximize the use of material performance, making the building itself lighter and stronger.

1.2 Sandwich structure, integrating technology and practical design wisdom

The design inspiration of sandwich panels comes from the "sandwich principle". The core materials are often composite materials with excellent physical properties such as polyurethane and rock wool, combined with double-sided metal or other material panels to form an integrated structure. This form gives Sandwich Panel Container House a natural advantage in thermal insulation, heat insulation, fire prevention and other properties, breaking through the limitations of traditional temporary buildings in comfort and durability.

1.3 Integrated structure, eliminating the hidden dangers of thermal bridges and leakage

In the past, the building forms often had the risk of thermal bridges and leakage at the connection parts, resulting in the inability to guarantee the quality of the indoor environment. The sandwich system of Sandwich Panel Container House not only achieves seamless splicing in design, but also effectively blocks the cold and heat exchange path and improves the overall airtightness. Excellent thermal performance also brings higher energy efficiency, providing a solid technical foundation for modern architectural concepts.

2. Assembly transformation: efficiency is the hard power of architecture

2.1 Module prefabrication, abandoning traditional "wet work"

Unlike traditional on-site pouring, bricklaying and wall-laying and other time-consuming processes, Sandwich Panel Container House relies on modular thinking for full-process prefabrication. Each building unit is standardized in the factory, and only needs to be assembled on site according to the design drawings, truly realizing "what you see is what you get". This transformation not only shortens the construction period, but also significantly improves the controllability of the overall project.

2.2 Building blocks and reshaping construction logic

In the past, buildings relied on complex construction processes and manual collaboration, but the building blocks structure adopted by Sandwich Panel Container House greatly simplified the construction process. Each component is prefabricated according to strict standards, and no heavy equipment and long-term operation are required for on-site assembly, and a stable structure can be formed in a short time. This high-efficiency, low-interference construction logic has become one of the important trends in modern architecture.

2.3 Reduce costs and increase efficiency, and the construction process is more economical

The compression of construction time directly leads to cost optimization. The construction period advantages, streamlined personnel and convenient transportation reflected by Sandwich Panel Container House save a lot of manpower and material resources for the entire construction cycle. At the same time, precise modular control also reduces the probability of rework and material waste, making the building more green, efficient and low-consumption.

3. Structural upgrade: a solid system born for extreme environments

3.1 Steel support to create a stable core structure

Unlike the "thin" impression given by lightweight materials, Sandwich Panel Container House does not compromise at the structural level. It uses a steel frame structure as the frame foundation, combined with a sandwich panel enclosure system to achieve a rigid and flexible structural system. Whether it is foundation bearing, vertical load, or horizontal resistance, it has a high degree of adaptability and provides reliable support for the entire building.

3.2 System synergy to improve overall structural strength

The strength of the structure is not only based on materials, but also requires system collaboration. Sandwich Panel Container House coordinates the mechanical behavior of each part through the close connection between the skeleton and the panel. Such a system not only enhances wind and earthquake resistance, but also effectively improves stability and safety levels, laying a solid foundation for the long-term use of the building under various conditions.

3.3 Environmental adaptation, calmly responding to extreme climate challenges

Modern buildings cannot only focus on internal comfort, but also need to face multiple tests of the external environment. The system structure of Sandwich Panel Container House not only has excellent physical strength, but also shows excellent climate adaptability. Whether it is high temperature, low temperature, strong wind or humidity, the building itself can maintain a stable state, not easy to deform, crack, or seep water, showing strong environmental resistance.