The concept of a container house has evolved from a niche architectural trend into a mainstream housing solution, celebrated for its durability, cost-effectiveness, and environmental credentials. As a leading force in prefabricated construction, Suzhou Shengshan Prefabricated Housing Manufacturing Co., Ltd understands that true quality in a container home lies in expert engineering, superior materials, and precise manufacturing. This comprehensive guide delves into the specifics of container living, providing the depth of information you need to make an informed decision.

Understanding the Container House: Beyond the Basic Box

A container house is a dwelling created primarily from recycled or new steel shipping containers. Its appeal stems from its modular nature, allowing for creative, scalable, and rapid construction. However, the success of such a project depends heavily on the expertise behind its conversion. At Suzhou Shengshan, our strong R&D team and rigorous production control ensure that the structural integrity of the container is enhanced, not compromised, during the transformation into a comfortable, safe, and long-lasting home.

Key Advantages of Choosing a Container Home

- Sustainability: Repurposing steel containers reduces construction waste and the demand for new raw materials.

- Strength and Durability: Built to withstand harsh marine environments, containers offer a robust structural frame.

- Cost Predictability: The modular nature allows for more accurate budgeting compared to traditional builds.

- Construction Speed: Prefabricated modules can be completed off-site, drastically reducing on-site build time.

- Design Flexibility: Containers can be stacked and combined in numerous ways to create unique architectural forms.

Exploring Your Options: Key Considerations for Your Project

Embarking on a container home project requires careful planning. Several specialized areas deserve your attention, often captured in common search queries from future homeowners. Addressing these long-tail keywords provides the specific, actionable information crucial for project success.

container house design and floor plans

A successful container home starts with a thoughtful design and functional floor plan. Unlike traditional houses, working with 20-foot or 40-foot modules requires efficient space planning.

Popular Design Layouts

- Single-Unit Compact: Ideal for studios, guest houses, or home offices, maximizing a 160-320 sq ft space.

- Multi-Container Combinations: Connecting containers side-by-side or end-to-end creates larger, open-plan living areas.

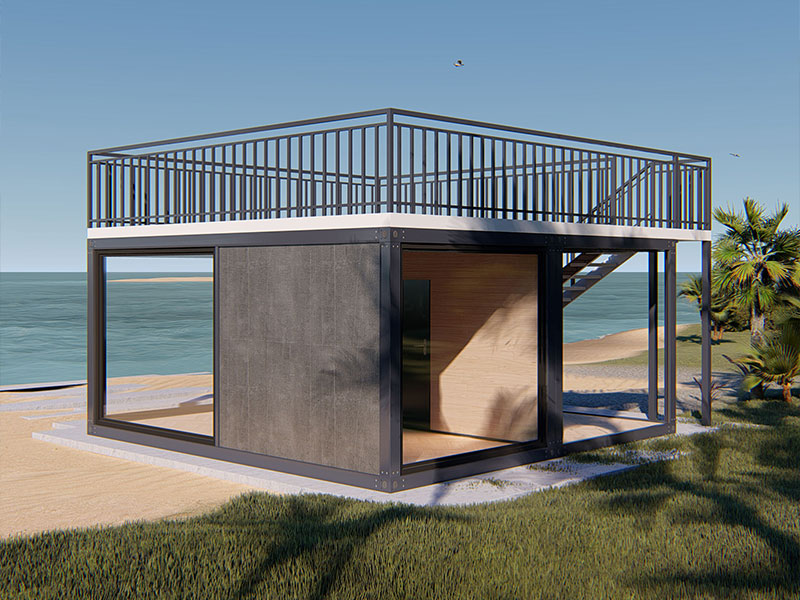

- Stacked Configurations: Utilizing vertical space with double-stacked containers for multi-level homes, often with atriums or internal staircases.

Design Tips for Optimal Living

- Strategically place large cut-outs for doors and windows to ensure cross-ventilation and natural light.

- Plan mechanical, electrical, and plumbing (MEP) routes early to integrate them within wall cavities or raised floors.

- Use high-quality insulation—such as spray foam—to combat thermal bridging in the steel frame, a critical step for comfort.

cost to build a shipping container home

Understanding the cost breakdown is vital. While often marketed as "cheap," a properly finished container home involves multiple expense layers beyond the container itself.

While a basic DIY conversion of a single container can seem inexpensive, a professionally built, code-compliant home with full amenities has a different cost profile. A custom, high-spec container home built by specialists may approach the cost per square foot of conventional construction but offers savings in time, waste, and unique design value [1].

| Cost Component | Approximate Percentage of Total Budget | Key Considerations |

|---|---|---|

| Containers & Site Prep | 15-25% | Includes purchase, delivery, foundation, and permits. |

| Structural Modifications | 20-30% | Cutting, reinforcing, welding, and framing openings. |

| Insulation & Interior Finishes | 25-35% | The most variable cost; quality here defines comfort. |

| Mechanical Systems | 15-20% | HVAC, plumbing, electrical, and renewable energy integration. |

| Exterior Cladding & Roofing | 5-10% | Optional for aesthetics and additional weather protection. |

insulation for steel container homes

Insulation is the most critical technical aspect of creating a livable container house. Steel is an excellent conductor of heat, making proper insulation non-negotiable for energy efficiency and preventing condensation.

Spray foam insulation provides superior thermal resistance and an air/moisture barrier but is typically more expensive. In contrast, panel-based insulation (like rigid foam boards) is easier for DIY installation and cost-effective but requires meticulous sealing to prevent thermal bridging [2].

| Insulation Type | Best Use Case | Pros | Cons |

|---|---|---|---|

| Spray Polyurethane Foam (SPF) | All climates, especially humid areas | Seals gaps completely, high R-value per inch, moisture barrier. | Higher cost, requires professional installation. |

| Rigid Foam Panels (XPS/EPS) | Walls, floors, and ceilings | Good R-value, moisture resistant (XPS), DIY-friendly. | Requires careful sealing at joints, can reduce interior space. |

| Mineral Wool Batts | Non-standard wall cavities | Fire resistant, sound absorbing, vapor permeable. | Lower R-value per inch, can settle if not installed tightly. |

building permits for container homes

Navigating local building codes and zoning regulations is a mandatory step that varies greatly by location. A container house is not automatically exempt from standard building requirements.

Common Permit Hurdles

- Zoning Classification: Is the land zoned for residential use? Are auxiliary dwelling units (ADUs) permitted?

- Structural Engineering Stamps: Plans often require a licensed engineer's approval to verify modifications don't compromise integrity.

- Energy Code Compliance: Meeting modern insulation and window efficiency standards must be demonstrated.

- Fire Safety: Egress requirements for bedrooms and the use of flame-retardant materials may be scrutinized.

Always consult with your local building department early in the design phase. Professional manufacturers like Suzhou Shengshan Prefabricated Housing Manufacturing Co., Ltd can often provide technical documentation and engineering calculations to support your permit application.

foundation options for container homes

The foundation provides a stable, level base and is crucial for preventing moisture damage to the steel structure. The choice depends on soil conditions, climate, budget, and design.

A concrete pier foundation is generally more cost-effective and suitable for stable soils and smaller projects. Conversely, a full concrete slab foundation provides superior stability, integrates well with radiant floor heating, and is better for expansive soils or larger multi-container projects, though at a higher cost [3].

| Foundation Type | Description | Ideal For |

|---|---|---|

| Concrete Piers | Individual concrete blocks or pillars set at key load points. | Sloping sites, good drainage, temporary or relocatable setups. |

| Strip Footings | Continuous concrete trenches under the container's long walls. | Moderate loads, frost-prone areas, providing a crawl space. |

| Concrete Slab | A single, level poured concrete platform. | Flat sites, permanent installations, integration with floor systems. |

| Helical Piles | Steel screws twisted into the ground, offering adjustable heights. | Very soft or unstable soils, sensitive sites with minimal excavation. |

The Professional Advantage: Why Manufacturing Quality Matters

While the DIY approach is popular, partnering with a professional manufacturer transforms the process. Suzhou Shengshan Prefabricated Housing Manufacturing Co., Ltd embodies the professional standards that ensure a superior end product.

Rigorous Quality Control from Start to Finish

- Material Selection: We enforce strict selection and audit procedures for raw material suppliers. Every batch of steel and composite panel undergoes incoming testing to ensure it meets our high standards for strength, corrosion resistance, and safety.

- Precision Engineering: Our strong R&D team can develop and manufacture based on your drawings or samples. Top-tier production process design ensures each structural modification—every cut and weld—is executed to preserve the container's inherent strength.

- Stable and Traceable Production: We make each batch of products stable and traceable, achieving efficient production control. This systematic approach guarantees consistency, whether you order one unit or fifty.

- Final Inspection: Our professional inspection team strictly monitors the quality of each product against stringent standards before it leaves our factory. Quality is our lifeline, ensuring the long-term durability and stability of your container house.

Frequently Asked Questions (FAQs)

1. Is a container house cheaper than a traditional house?

It can be, but not always. While the base container cost is low, total expenses for professional modifications, high-performance insulation, utilities, and interior finishes add up. The primary savings are often in reduced construction time, lower waste, and sometimes in labor. A budget-conscious, DIY-heavy project can be very cost-effective, while a turn-key, architect-designed home may rival conventional costs.

2. How long does a container home last?

A properly maintained container home can last for decades. The Corten steel used in shipping containers is weathering steel, designed to withstand harsh conditions. The key to longevity lies in the quality of conversion: preventing corrosion (through proper sealing, insulation, and paint), managing condensation with excellent insulation, and ensuring all structural modifications are done correctly.

3. Are container homes hot in summer and cold in winter?

Steel is a thermal conductor, so an uninsulated container will be extreme in temperature. However, with the insulation for steel container homes detailed above—especially a continuous thermal break like spray foam—a container home can be as energy-efficient, if not more so, than a traditional stick-built house. Strategic window placement for passive cooling and heating also plays a major role.

4. Can I stack containers to make a two-story home?

Yes, stacking is a common technique. However, it requires significant professional engineering. The lower containers must be structurally reinforced to bear the load, and the containers must be properly welded or bolted together. This is a critical area where professional manufacturing, like that at Suzhou Shengshan, is essential to ensure safety and compliance with building codes.

5. What are the biggest challenges when building a container house?

The main challenges include: 1) Obtaining building permits for container homes, as some local jurisdictions may be unfamiliar with them; 2) Sourcing quality professionals (welders, engineers) if not using a turn-key manufacturer; 3) Solving the insulation and condensation puzzle effectively; and 4) Working within the fixed width (8 feet) of a container, which requires creative space planning for furniture and utilities.

Building a container house presents a unique opportunity to create a durable, sustainable, and personalized home. Success hinges on detailed planning in container house design and floor plans, a clear understanding of the true cost to build a shipping container home, and expert execution of critical systems like insulation for steel container homes. Furthermore, navigating logistics like building permits for container homes and choosing the right foundation options for container homes are fundamental steps. By prioritizing quality manufacturing and engineering—where companies like Suzhou Shengshan Prefabricated Housing Manufacturing Co., Ltd excel—you invest in a home that is not only aesthetically striking but also built to deliver comfort, efficiency, and value for years to come.

References

[1] Smith, J., & Davis, L. (2022). *Comparative Economic Analysis of Alternative Housing Construction Methods*. Journal of Sustainable Building. (For cost comparison data).

[2] International Code Council. (2021). *International Energy Conservation Code (IECC)*. ICC. (For insulation standards and best practices).

[3] Wilson, A. (2023). *Foundation Systems for Modular and Non-Traditional Structures*. Civil Engineering Review. (For foundation type analysis and suitability).