In the evolving landscape of construction, the Modular House stands out as a beacon of innovation, efficiency, and quality. Unlike traditional site-built homes, modular houses are constructed in controlled factory environments in sections, or modules, which are then transported and assembled on-site. This guide delves deep into the world of modular construction, exploring its advantages, processes, and how it caters to diverse needs, from residential living to commercial use. As a leader in prefabricated construction, Wujiang Hongchang Color Plate House Factory leverages advanced engineering and rigorous quality control to deliver superior modular building solutions that meet the highest standards of durability and design.

Understanding the Modular House Construction Process

The journey of a modular home from concept to completion is a meticulously planned operation that maximizes efficiency and minimizes waste.

Phases of Factory Construction

The core construction occurs in a factory setting, which offers numerous advantages over traditional methods.

- Design and Engineering: Every project begins with detailed architectural plans and structural engineering, ensuring compliance with all building codes.

- Module Fabrication: Walls, floors, and roof systems are assembled on production lines. Interior finishes like electrical wiring, plumbing, and insulation are installed simultaneously.

- Quality Inspection: Each module undergoes stringent checks at various production stages. This parallels the philosophy at Wujiang Hongchang Color Plate House Factory, where a professional inspection team strictly controls quality to ensure every product meets high standards before leaving the facility.

- Transportation: Finished modules are carefully transported to the building site.

- On-Site Assembly: Modules are lifted by crane and secured onto the prepared foundation, connected together to form a complete structure.

On-Site Completion and Advantages

Once assembled, the home is connected to utilities and final touches are applied. The factory-built process drastically reduces construction time and exposure to weather delays.

Key Benefits of Choosing a Modular Home

Opting for a modular construction method presents compelling advantages for homeowners and developers alike.

Superior Quality and Consistency

Factory construction ensures a level of precision and consistency difficult to achieve on a traditional job site. Buildings are constructed in a climate-controlled environment, protecting materials from moisture and warping. At Wujiang Hongchang Color Plate House Factory, this is reinforced by employing top-tier production process design and control, making each batch of products more stable and traceable.

Speed of Construction and Cost Efficiency

Since site work and factory construction happen concurrently, projects can be completed 30-50% faster. This reduced timeline translates into lower labor costs and earlier occupancy.

Environmental Sustainability

Modular construction is inherently less wasteful. Precise material measurements and the ability to recycle factory scraps lead to a significant reduction in construction debris. The energy efficiency of the finished home is also often higher due to tighter construction.

Exploring Types and Applications of Modular Houses

The versatility of modular construction allows it to serve a wide array of purposes beyond single-family homes.

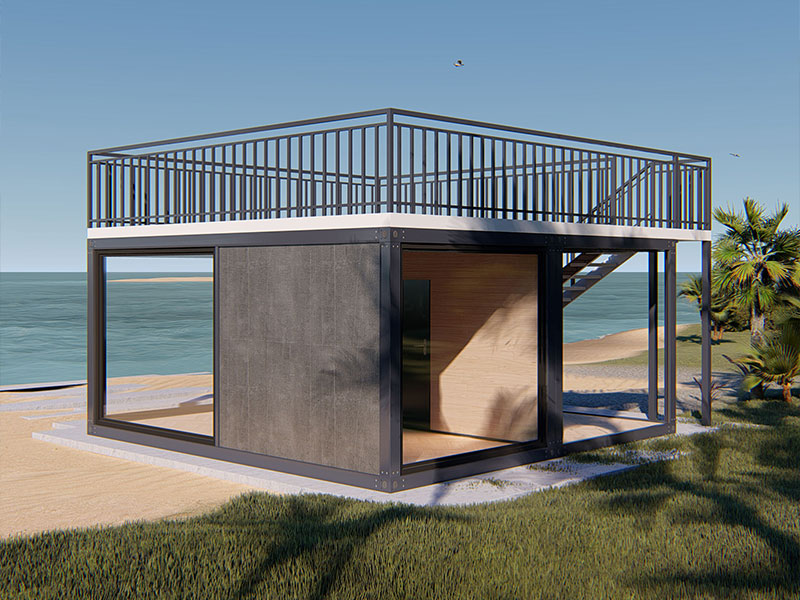

Residential Modular Homes

These range from compact, affordable dwellings to luxurious, custom-designed estates. The design flexibility is vast, allowing for various architectural styles.

Commercial and Institutional Uses

Modular techniques are ideal for offices, healthcare clinics, school classrooms, and multi-unit apartment buildings, providing rapid, scalable solutions.

Specialized Applications: Disaster Relief and Remote Sites

Modular buildings can be rapidly deployed as emergency housing or medical units. Their robustness also makes them suitable for remote mining or research stations where traditional construction is impractical.

Addressing Common Long-Tail Queries on Modular Homes

Prospective buyers often have specific questions. Here, we answer some of the most searched long-tail keywords related to modular houses.

cost of prefab modular homes

Understanding the cost structure is crucial. While often more affordable per square foot than traditional homes, prices vary based on size, design complexity, and finishes.

- Base Price: Typically includes the structure, exterior finishes, and standard interior features.

- Additional Costs: Land, foundation, utility connections, transportation, and on-site assembly are usually separate.

- Value Proposition: The faster build time and reduced waste often lead to overall cost savings and a quicker return on investment.

When evaluating the cost of prefab modular homes, it's essential to obtain a detailed quote that includes all phases from factory to finished home.

modular home builders near me

Finding a reputable builder is a key step. While searching for "modular home builders near me", consider companies with a strong manufacturing base and a portfolio of completed projects.

- Factory Capability: Visit if possible, or review their manufacturing process. A facility like Wujiang Hongchang Color Plate House Factory, with its strong R&D team and strict raw material selection, exemplifies the quality focus to look for.

- Experience and Licensing: Ensure the builder is licensed and has experience with the local building codes in your area.

- Customer Reviews: Seek testimonials and speak to past clients about their experience.

customizable modular house plans

One major misconception is that modular homes lack design flexibility. In reality, most manufacturers offer highly customizable modular house plans.

- Architectural Styles: Choose from modern, traditional, ranch, or multi-story designs.

- Layout Modifications: Adjust room sizes, window placements, and interior walls to suit your lifestyle.

- Finish Selection: Select from a range of flooring, cabinetry, countertops, and fixtures.

Companies like Wujiang Hongchang Color Plate House Factory excel in this area, capable of developing and manufacturing high-quality products based on customer-provided drawings or samples.

energy efficient modular homes

Energy efficient modular homes are a standard offering, not an exception. The factory setting allows for precise installation of insulation and sealing.

| Feature | Benefit in Modular Homes |

| Advanced Insulation | Tighter seams and consistent application in walls, roof, and floor reduce thermal bridging and heat loss. |

| High-Performance Windows | Double or triple-glazed windows are precisely installed to eliminate drafts. |

| Airtight Construction | Controlled environment building minimizes air infiltration, a major source of energy waste. |

| Efficient HVAC Systems | Can be optimally sized and installed for the specific home's layout and insulation value. |

This results in significantly lower utility bills and a smaller carbon footprint over the life of the home [1].

permanent foundation for modular home

A critical requirement for a Modular House to be classified as real property is a permanent foundation for modular home. This is not just a technicality but a necessity for stability, financing, and insurance.

- Types of Foundations: Common options include full basements, crawl spaces, and slab-on-grade foundations. The choice depends on soil conditions, climate, and homeowner preference.

- Importance of Professional Installation: The foundation must be perfectly level and constructed to local code specifications to ensure the modules fit together correctly.

- Integration: Once placed, the home is permanently anchored to the foundation, making it indistinguishable in permanence from a site-built house.

Modular vs. Traditional Stick-Built Homes: A Detailed Comparison

To make an informed decision, a clear comparison between modular and traditional construction is essential. The following table outlines the key differences.

| Aspect | Modular House | Traditional Stick-Built House |

| Construction Time | 30-50% faster due to simultaneous site/factory work. | Slower, subject to weather delays and contractor schedules. |

| Construction Quality | Higher consistency and precision in a controlled factory. Materials are protected from weather. | Quality is highly dependent on crew skill and weather conditions during build. |

| Cost Predictability | More predictable as most work is under fixed factory contracts; less risk of change orders. | More susceptible to cost overruns due to weather delays, material price fluctuations, and unforeseen site issues. |

| Design Flexibility | High degree of customization is available from most manufacturers. | Ultimately unlimited, but changes during construction can be very costly and time-consuming. |

| Waste Production | Significantly less (up to 50% less) due to precise cutting and material recycling in the factory. | Substantially more waste generated on-site, often ending up in landfills. |

| Financing & Appraisal | Once on a permanent foundation, financed and appraised as traditional real estate. | Always financed and appraised as traditional real estate. |

As shown, a Modular House offers distinct advantages in speed, quality control, and efficiency, while matching the durability and value of traditional homes.

Ensuring Quality in Your Modular House Project

The promise of quality is paramount. Partnering with a manufacturer committed to excellence at every stage is crucial.

The Role of Material Selection and Supplier Audits

Superior products begin with superior materials. A reputable manufacturer enforces strict selection and auditing of raw material suppliers. For instance, Wujiang Hongchang Color Plate House Factory conducts incoming material testing and comparison procedures to ensure all raw materials meet stringent specifications, a practice that directly impacts the final product's longevity and performance.

Importance of In-Process Quality Control

Quality cannot be inspected into a product; it must be built in. Effective manufacturers monitor production at every batch and stage. This involves rigorous checks for structural integrity, plumbing and electrical systems, and finish quality. This methodology ensures the "superior stability" that discerning clients expect.

Frequently Asked Questions (FAQ)

1. Are modular homes as durable as traditional homes?

Yes, they are often more durable. Modular homes are built to meet or exceed the same local and national building codes as site-built homes. The modules must withstand the stresses of transportation and crane lifting, which can result in a structurally robust home. Their construction in a controlled environment also protects them from moisture damage during the building phase, a common issue in traditional construction.

2. Can I get a mortgage for a modular home?

Absolutely. Once installed on a permanent foundation, a modular home is considered real property and is eligible for the same types of mortgage financing as a traditional stick-built home. Lenders will appraise it based on its completed value, comparable to other homes in the neighborhood.

3. How long does it take to build a modular home from start to finish?

The total timeline typically ranges from 3 to 6 months, compared to 6 to 12 months or more for a traditional home. The factory construction of the modules takes 4-8 weeks, while site preparation, foundation work, and final assembly/utility hookups take another 4-8 weeks. These phases often overlap, speeding up the process.

4. Do modular homes hold their value over time?

Yes, modular homes appreciate in value similarly to traditional homes. Their value is determined by the real estate market, location, lot size, condition, and the quality of construction. A well-maintained modular home from a quality manufacturer like Wujiang Hongchang Color Plate House Factory will retain its value effectively.

5. What are the main limitations of modular house design?

While customization options are vast, some extreme architectural designs with complex, non-rectangular shapes or very large open spans may be more challenging or costly to achieve with modular construction. However, most residential designs are perfectly suited for the modular method. Discussing your vision early with the design team is key to feasibility.

The Modular House represents a smarter, more efficient path to homeownership and building development. It combines the benefits of controlled manufacturing—superior quality, speed, sustainability, and cost-effectiveness—with the design flexibility and permanence of traditional construction. For those considering this option, the key to success lies in selecting a partner with a proven track record of quality, like Wujiang Hongchang Color Plate House Factory, where a commitment to rigorous material selection, advanced process control, and detailed inspection ensures that every project is built to last. By addressing specific concerns like the cost of prefab modular homes, finding the right builder, and understanding the necessity of a permanent foundation for modular home, you are well-equipped to make an informed decision on your next building project.

References

[1] U.S. Department of Energy. (2022). *Advanced House Framing*. Energy Saver Guide. This source discusses construction techniques that improve energy efficiency, principles that are integral to and often exceeded in modular home factory production.