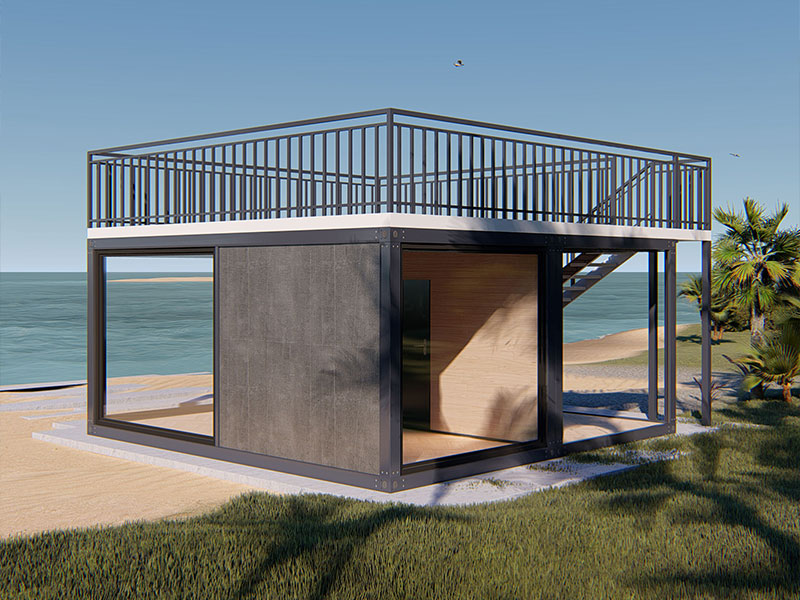

Welcome to the future of adaptable construction. The Detachable Container House represents a significant leap forward in modular building technology, offering unparalleled flexibility, cost-efficiency, and speed of deployment. Unlike traditional shipping containers that require heavy machinery for relocation and modification, the detachable variant is designed for disassembly, flat-packing, and reassembly. This makes them ideal for temporary housing, remote site offices, emergency shelters, and even permanent, scalable residences. We aim to provide a professional, in-depth analysis of this innovative building solution, covering everything from the underlying design principles to detailed financial projections and assembly guides. Whether you are an investor, a developer, or a homeowner seeking a sustainable and portable living solution, understanding the inherent advantages and logistics of these structures is essential for making an informed decision. By focusing on the structural integrity, logistical benefits, and financial implications, this guide serves as your comprehensive resource for navigating the world of modular container housing.

Understanding Versatility and Design: Why Modularity Matters

What Sets Detachable Design Apart from Traditional Construction?

The fundamental distinction between a Detachable Container House and conventional building methods lies in its inherent capacity for full lifecycle mobility. Traditional stick-built homes are designed to be permanent, fixed structures, making any relocation economically prohibitive and logistically impossible. Even standard, welded shipping container homes, while highly durable, are monolithic units that require large cranes and specialized transport permits when moving between sites. In stark contrast, the detachable version is engineered with a bolted or locking pin system, allowing skilled teams to dismantle the unit into its component parts—roof, floor, columns, and wall panels—in a matter of hours. This flat-pack capability drastically reduces transportation costs, as multiple units can be stacked and shipped on a single standard freight truck or ocean container. This design philosophy is not merely about portability; it is about maximized utility and minimizing waste throughout the building's operational life. The efficiency gained in logistics directly translates into substantial cost savings and a reduced environmental footprint, making modularity the defining feature that sets these modern structures apart in the construction industry landscape. This design freedom also allows for easy expansion or reconfiguration of the unit simply by adding or removing wall panels or connecting additional modules. This level of design agility is transforming how industries approach temporary and permanent infrastructure needs globally.

- Structural Flexibility: The bolted connections ensure that the entire frame can be repeatedly assembled and disassembled without compromising the structural integrity of the steel frame.

- Logistical Efficiency: Dismantled units can be stacked up to 8-10 units high for transit, dramatically lowering shipping and freight forwarding costs per unit compared to single welded containers.

- Foundation Requirements: They typically require only a simple, level foundation (concrete pads, piers, or gravel), unlike the complex, time-consuming deep foundations required for traditional structures.

- Code Compliance: Modern detachable designs are often built to specific international building codes and standards, simplifying the permitting process for temporary or remote installations.

| Feature | Detachable Container House (Modular) | Traditional Stick-Built Home | Standard Welded Shipping Container Home |

| Relocation Complexity | Low (Flat-packed, standard freight) | Impossible (Fixed foundation) | High (Requires specialized transport, cranes) |

| Foundation Need | Simple ground-level piers/pads | Complex, deep foundation | Requires level ground/minimal foundation |

| Assembly Time | Fast (2-4 hours per unit) | Slow (Weeks to months) | Moderate (Welding/cutting required) |

Deep Dive into Financials: Calculating the True Investment

Analyzing the Lifecycle Expenses: Manufacturing vs. Cost of Reassembling Detachable Container House

When evaluating the total investment for a Detachable Container House, it is crucial to look beyond the initial purchase price and consider the full lifecycle costs, particularly the recurring expense associated with mobility. The initial manufacturing cost covers the materials, fabrication, and factory assembly before the unit is flat-packed. This phase is highly efficient due to mass production techniques and controlled factory environments, which generally result in a lower cost per square foot compared to custom on-site construction. However, the unique financial advantage lies in the deferred expenses, specifically the Cost of Reassembling Detachable Container House. Unlike traditional buildings that become obsolete once a site is finished, detachable units retain their value because they can be moved and reused. The reassembly cost typically involves labor, a small crane or forklift for lifting the roof frame, and minor utility reconnections. This cost is a fraction of the expense involved in demolition and new construction. Investors must calculate the Return on Investment (ROI) based on the number of times the unit can be successfully relocated and redeployed, turning what would typically be a depreciating asset into a reusable infrastructure tool. Proper maintenance and careful handling during disassembly are key to minimizing long-term repair costs, further maximizing the investment's lifespan and proving the fiscal sensibility of choosing a truly portable construction method for dynamic business or housing needs.

- Initial Cost Efficiency: Factory production minimizes labor hours and material waste, leading to competitive upfront pricing for bulk orders.

- Transport Savings: Shipping a stack of 8 units flat-packed costs roughly the same as shipping one standard container unit, generating exponential savings on large-scale projects.

- Labor Skill: Reassembly requires general labor with clear instruction, not highly specialized construction trades, keeping reassembly costs predictable and low.

- Depreciation vs. Reusability: The ability to dismantle and reuse the structure transforms its accounting treatment from a rapidly depreciating fixed asset to a long-term, movable piece of equipment.

| Expense Category | Initial Manufacturing Cost (One-time) | Cost of Reassembling Detachable Container House (Recurring) | Benefit Factor |

| Structure & Materials | Covers all steel, panels, fittings | Minimal (inspection, tightening bolts) | High Durability/Low Maintenance |

| Transportation | Flat-pack shipping rate | Reduced rate due to high stackability | Major Logistical Savings |

| On-Site Labor | Zero (Factory work) | Low (2-4 workers, 2-4 hours) | Minimal Downtime |

Detachable Flat Pack Container Homes Review: Kit vs. Turnkey Options

When purchasing a Detachable Container House, prospective owners are typically faced with two primary procurement paths: the bare "Kit" option and the fully provisioned "Turnkey" solution. A crucial part of any comprehensive Detachable Flat Pack Container Homes Review is understanding the trade-offs between these two formats. The kit option provides the basic structural components—the steel frame, the roof, the floor base, and standard wall/insulation panels—leaving the purchaser responsible for all internal finishes, plumbing, electrical wiring, HVAC, and custom windows/doors. This route offers the greatest cost savings upfront and maximum design customization, making it popular with experienced builders or DIY enthusiasts with access to local subcontractors. Conversely, the turnkey option arrives with a near-complete fit-out: internal walls, basic kitchen and bathroom modules, pre-installed wiring, and lighting fixtures are all included. While the turnkey solution has a significantly higher initial price, it dramatically reduces on-site work, risk, and lead time, often being ready for occupancy within days of arrival. Choosing between the two depends entirely on the buyer’s budget, technical expertise, and desired speed of deployment. While the kit provides flexibility, the turnkey route provides predictable quality and immediate functionality, which is often preferred for high-volume commercial or rental applications where time is money. Ultimately, the review process should balance financial constraints against the total labor hours required post-delivery for either solution.

- Kit Option Suitability: Best for projects with long timelines, specialized interior needs, or where the buyer has high-level in-house construction capabilities.

- Turnkey Value: Ideal for rapid deployment, emergency accommodation, or sites where construction labor is scarce or expensive.

- Interior Customization: Kits allow for full control over panel materials, flooring, and appliance selection; turnkey is generally standardized.

- Warranty and Compliance: Turnkey units often come with consolidated warranties covering all major systems, whereas kits require separate warranties for components installed on-site.

| Criteria | Kit Option (DIY focus) | Turnkey Option (Ready-to-use) |

| Initial Cost | Lowest upfront price | Highest initial price |

| On-Site Workload | High (Electrics, Plumbing, Finishing) | Low (Just connections/furnishing) |

| Time to Occupancy | Weeks/Months | Days |

Practical Implementation and User Assembly

The Essential Portable Container Office Installation Guide for Commercial Use

For businesses requiring flexible on-site infrastructure, such as construction firms, mining operations, or disaster relief agencies, the Portable Container Office Installation Guide is an indispensable resource. Unlike permanent structures, these modular offices provide immediate, professional workspace that can be rapidly deployed to any location with access to level ground. The initial deployment requires thorough site preparation, which, while minimal compared to traditional building, is critical for stability and longevity. This process begins with ensuring the chosen location is flat and stable, often involving the placement of concrete piers or steel ground beams to distribute the load evenly. Crucially, the installation process emphasizes efficiency: the main challenge is safely hoisting the roof section onto the corner posts, typically achieved using a small forklift or a truck-mounted crane. Once the roof is secured, the wall panels are slotted into place—a task often requiring only two or three workers. This guide stresses the importance of following the manufacturer’s instructions precisely, especially regarding the sequence of bolting the corner posts, as this determines the structural integrity of the final unit. Proper commercial deployment also includes setting up utility access, such as connecting external power to a main electrical panel and plumbing for small kitchenettes or bathrooms, ensuring that the finished office is fully functional and compliant with local safety standards. The ability to deploy a high-quality office in less than a day is a key factor in the growing demand for these Modular Detachable Container Buildings in dynamic commercial environments.

- Site Preparation: Ensure a 100% level surface. Uneven weight distribution can compromise the structure's locking mechanisms.

- Safety First: Always use certified lifting gear and rigging methods to secure the roof frame during hoisting, and adhere to local site safety protocols.

- Utility Connection Checklist: Before moving to interior fit-out, verify the secure, waterproof connection of all external electrical lines and water inlets.

- Anchoring: For long-term or high-wind environments, use ground anchors or tie-downs to secure the unit to the foundation, as specified in the local building codes.

Step-by-Step Setup: Mastering DIY Detachable Container Home Kits

Embracing the challenge of assembling your own Detachable Container House using DIY Detachable Container Home Kits is an empowering and cost-effective endeavor, but it requires careful planning and a methodical approach. The kits are engineered to be user-friendly, relying on simple mechanical fasteners rather than specialized welding, making them accessible to a homeowner with basic tool knowledge. The process starts with identifying and laying out all components clearly, distinguishing between the floor frame, roof frame, corner posts, and various wall and door panels. The first critical phase involves assembling the floor frame and ensuring it is perfectly square and level on your prepared foundation; any slight skew here will complicate all subsequent steps. Next, the corner posts are bolted into the floor frame. The most physically demanding part is lifting the assembled roof frame onto the posts. While small kits might be manageable with temporary supports and manual lifting, most units benefit significantly from a light-duty crane or telescopic forklift to ensure safe and precise placement. Once the roof is bolted down, the structural envelope is complete, and the quick-install wall panels are simply slotted into the frame channels, followed by windows and doors. The true value of these kits is realized when considering the complexity of traditional framing—the Detachable Container House bypasses this entirely, saving days or weeks of carpentry labor. By simplifying the structural phase, the homeowner can dedicate more time and budget to customizing the interior finishes.

- Tool Requirements: Typically include basic wrenches, socket sets, levels, measuring tapes, and a power drill for fastening components.

- Team Size: While assembly is simple, a minimum of 2-3 people is recommended for safety and ease of handling the heavier components like the roof frame.

- Weather Contingency: Plan the main assembly phase (frame and panel insertion) for a dry day, as water ingress before sealing the roof can lead to complications.

- Post-Assembly Sealing: After assembly, use a high-quality sealant (like silicone or polyurethane) to secure all panel joints and roof edges for superior weatherproofing and insulation performance.

FAQ

How durable and long-lasting is a Detachable Container House compared to a conventional home?

A well-maintained Detachable Container House is exceptionally durable, often designed with a structural lifespan comparable to or exceeding standard mobile or manufactured homes. The structure is typically built using galvanized steel frames, which are highly resistant to rust and corrosion, providing a robust skeleton for the unit. High-quality Sandwich Panels (such as EPS, PU, or Rock Wool) are used for walls and roofing, offering excellent insulation properties and fire resistance. The longevity of the unit is maximized by the fact that it can be regularly inspected during relocations and has minimal exposure to on-site construction variables that often affect the quality of traditional builds. While a standard brick-and-mortar home might last 80-100 years, a high-spec detachable container unit can easily provide 20-30 years of continuous use, with the added advantage that, unlike fixed homes, it can be refurbished or relocated to a better-suited environment when required. This movability ensures that the asset retains utility and value far longer than its fixed counterparts. The use of strong Modular Detachable Container Buildings materials also makes them very resilient to severe weather, provided they are properly anchored to the foundation as outlined in the installation guide.

What local regulations and permits are typically required for installing a Portable Container Office Installation Guide?

Permit requirements for a Detachable Container House, especially a commercial one following a Portable Container Office Installation Guide, vary significantly by jurisdiction and the intended duration of use. Generally, if the structure is classified as a "temporary building" (often defined as less than 180 days in one location), the permitting process may be simpler, sometimes requiring only a temporary placement permit or a commercial zoning review. However, if the structure is permanently anchored and connected to utility services (water, sewer, permanent power), most localities will classify it as permanent construction. In this case, it must comply with all local building codes, including foundation requirements, snow load, wind resistance, and fire safety codes. Prospective owners should always start by consulting the local planning and zoning department to determine the specific requirements. They will need to confirm if the unit’s design specifications (e.g., insulation R-values, electrical wiring standards) meet local mandates. It is also important to note that the easy assembly of DIY Detachable Container Home Kits does not exempt the final structure from these necessary inspections and local authority approvals.