The modern construction landscape is rapidly evolving, driven by demands for efficiency, sustainability, and value. For B2B buyers, project developers, and procurement specialists, understanding the technical and economic merits of prefabricated construction is paramount. This article delves beyond surface-level benefits, offering an engineer-level analysis of why modular building methods represent a strategic advantage for commercial and industrial projects.

In-Depth Analysis of Core Advantages

1. Unmatched Project Timeline Efficiency & Predictability

The most cited advantage of a prefabricated house or structure is significantly reduced on-site construction time. This efficiency stems from concurrent workflows: site foundation work proceeds simultaneously with module fabrication in a controlled factory environment. For a standard commercial prefabricated warehouse construction time can be reduced by 40-60% compared to traditional methods. This predictability is a critical risk-mitigation factor for project financing and ROI calculations.

For instance, while traditional construction is sequential and highly susceptible to weather delays, prefabrication decouples the critical path from on-site conditions. The table below contrasts the two project phases:

| Project Phase | Traditional Construction | Prefabricated Construction |

|---|---|---|

| Foundation & Structure | Sequential, weather-dependent, prone to trade scheduling conflicts. | Concurrent; structure is built off-site in parallel with site prep, unaffected by weather. |

| Enclosure & Weatherproofing | Occurs late in the schedule, exposing unfinished work. | Modules arrive fully enclosed, making the building weather-tight within days of erection. |

2. Superior Quality Control & Material Consistency

Factory production enables a level of precision and quality assurance nearly impossible to achieve on a traditional job site. In a facility like that of Suzhou Shengshan Prefabricated Housing Manufacturing Co., Ltd, every component is manufactured under strict protocols. Their professional inspection team enforces rigorous quality gates, from raw material auditing—ensuring the integrity of fire resistant prefabricated house materials—to dimensional tolerances and weld integrity. This controlled process results in products with superior stability and traceability, where each batch's performance data is recorded.

The industry is advancing rapidly. According to the latest report by the International Code Council (ICC) and Modular Building Institute (MBI), updates to the 2024 International Building Code (IBC) include more explicit provisions for the inspection and approval of prefabricated structural elements, further institutionalizing the quality standards that leading manufacturers already exceed. This regulatory evolution provides greater assurance for commercial clients regarding compliance and safety.

Source: Modular Building Institute - "2024 Annual Report & Construction Industry Outlook" - Link

3. Lifecycle Cost-Effectiveness and Transparent Budgeting

While initial capital expenditure is a key consideration, a true prefabricated house cost per square meter analysis must evaluate Total Cost of Ownership (TCO). Prefabrication offers distinct advantages:

- Reduced Material Waste: Factory precision cutting and bulk purchasing can reduce waste by up to 90% compared to site-built projects.

- Lower Labor Costs & Overtime: Streamlined assembly reduces high-cost on-site labor hours and minimizes overtime premiums.

- Enhanced Energy Performance: Tight construction tolerances and integrated insulation in panels eliminate thermal bridging common in stick-built structures, directly contributing to an energy efficient prefabricated office building. This translates to decades of reduced operational expenditure on heating and cooling.

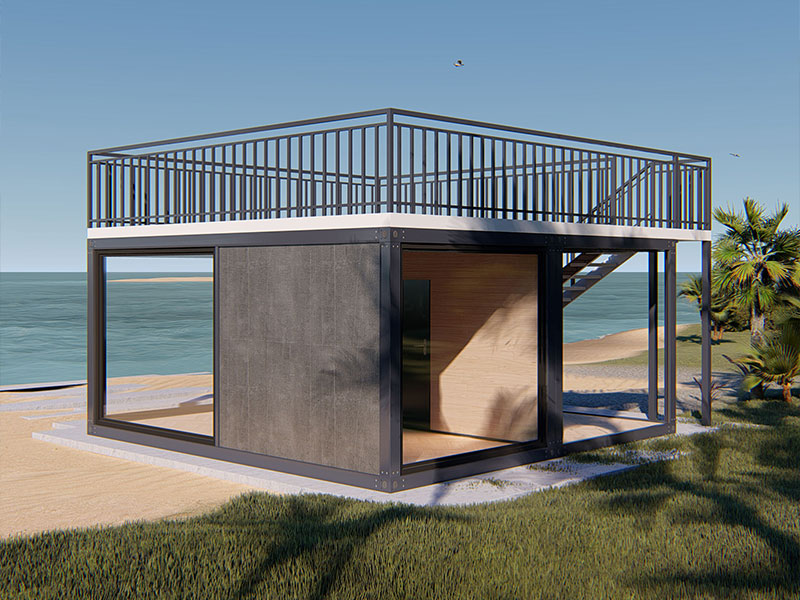

4. Design Flexibility and Engineering Innovation

The misconception that prefabrication limits design is outdated. Modern CAD/CAM and BIM (Building Information Modeling) integration allow for highly customized solutions. This is particularly relevant for specialized industrial needs, such as long span prefabricated house design specifications. Engineers can design clear-span structures using fabricated steel trusses or proprietary beam systems that are precision-engineered off-site and rapidly assembled on location. Companies with strong R&D capabilities, like Suzhou Shengshan, can develop and manufacture high-quality products based on precise client drawings, enabling bespoke solutions for complex operational requirements.

5. Enhanced Safety and Sustainable Construction Practices

Safety is paramount, both during construction and throughout the building's lifespan. Factory settings drastically reduce the risks associated with working at heights, inclement weather, and congested sites. From a sustainability perspective, the efficiencies in material use, reduced site disturbance, and potential for disassembly and relocation make prefabrication a cornerstone of green construction. The inherent quality of construction also contributes to durability and resilience.

Frequently Asked Questions (FAQ)

Q1: How does the structural integrity of a prefabricated building compare to traditional construction?

A1: When engineered and manufactured to international standards (e.g., ISO, AISC, Eurocode), prefabricated buildings often exceed the structural integrity of site-built structures. Factory-controlled welding, bolting, and material consistency ensure each connection meets or exceeds design specifications, a process rigorously validated by in-house quality teams.

Q2: Can prefabricated buildings be expanded or reconfigured in the future?

A2: Yes, modularity is a core principle. Well-designed prefabricated systems are inherently scalable. Future expansions can be planned for, and modules can often be added, relocated, or repurposed with minimal disruption, protecting your long-term asset value.

Q3: What are the limitations on the size or height of a prefabricated structure?

A3: Technological advancements have largely eliminated traditional size constraints. Multi-story commercial buildings, wide-span warehouses, and complex facilities are now common. Specific long span prefabricated house design specifications are determined by engineering analysis and transportation logistics, which a reputable manufacturer can expertly navigate.

Q4: How are utility systems (plumbing, electrical, HVAC) integrated?

A4: In high-quality prefabrication, MEP (Mechanical, Electrical, Plumbing) systems are partially or fully integrated within the modules or panels during factory assembly. This "plug-and-play" approach ensures systems are installed correctly, tested before shipment, and dramatically reduces on-site integration time and errors.

Q5: What is the typical warranty and lifespan of a commercial prefabricated building?

A5: Lifespans of 30+ years are standard for steel-framed prefabricated buildings when properly maintained. Warranties vary but typically cover the structural frame for 10-20 years and wall/roof systems for 5-10 years, provided by manufacturers who stand behind their controlled production processes, such as those with stringent supplier auditing and batch testing protocols.